GROUTING TECHNOLOGY TO PREVENT LEAKAGE AND CARRY OUT REPAIRS TO SEWERS

Sewage Discharge Tunnel Leakage Detection And Restoration

1. Project Background

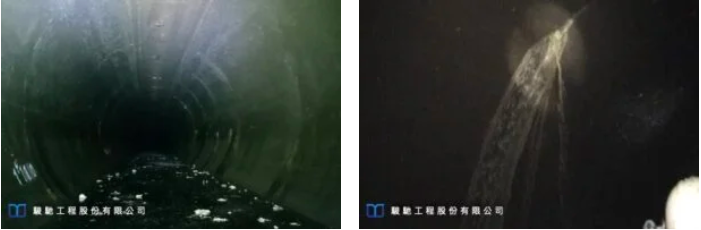

Grouting Technology – In this tunnel leakage case, a deep underground sewage discharge tunnel was responsible for the important task of transporting domestic sewage to the treatment plant.

After the discharge tunnel had been in use for a period of time, localized damage had been caused by probable factors such as subsidence, earthquake, neighboring construction, excavation and precipitation.

In order to avoid environmental pollution caused by sewage flowing out of the fissures, and groundwater flowing into the tunnel with mud and sand, causing the stratum to hollow out and cause sudden subsidence disasters, the management unit specially commissioned a professional tunnel leakage detection and repair company to carry out the whole line maintenance work of the whole line to ensure safety to life and property of vehicles on the surface above and pedestrians.

—

2. Solution

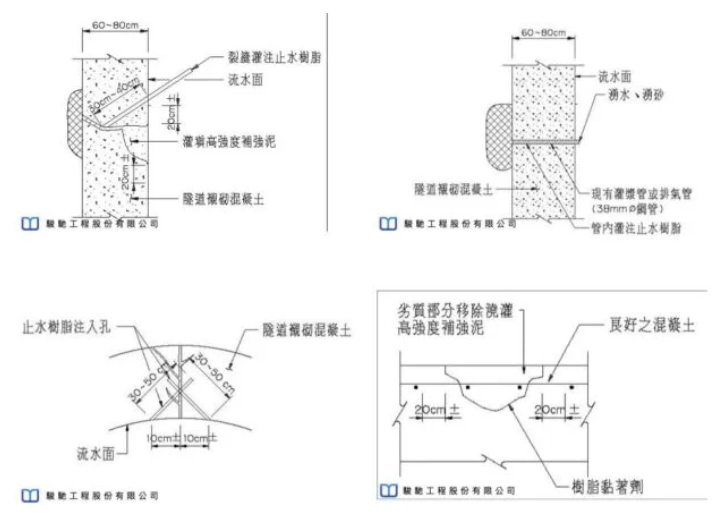

Sewage tunnel lining damage could be divided into four categories:

(1) water gushing from holes

(2) water leakage from grouting and exhaust pipes

(3) water leakage from construction joints & cracks

(4) protective layer peeling, damage, steel rebar rust.

The solution plan procedures follow:

(a) safety maintenance

(b) visual classification

(c) ground penetrating radar and non-destructive detection of steel rebar;

(d) performing repair

(e) examine result

(f) site clean-up. Because the sewage tunnel was full of combustible methane, toxic gas and foul smell, work safety and the selection of machinery and equipment became the primary considerations for this project.

—

3. Works Design

Because of the narrow entrance of the sewage tunnel, large-scale grouting equipment cannot enter, making the cement system and hot bitumen grout unusable.

The construction design used non-toxic hydrophilic elastic/rigid resin grout, high-strength epoxy, non-shrinking cement, rebar anti-rust protective agent, rebar anchor and steel wire mesh; the hollowed-out part of the stratum to be filled with non-expandable resin material; the cracks in the lining to be sealed, bonded and reinforced with rigid resin material; large voids to be filled with non-shrinking cement with rebar anchors and steel wire mesh; rebar corrosion prevention to be supplemented with anti-rust protective agent mixed with non-shrinking cement for protection; the exterior of all repair locations to be protected by high-strength epoxy and surface refurbishment to prevent the sewage and toxic gases in the tunnel from re-eroding the repair location.

—

4. Project Process

The sewage tunnel under repair had a diameter of about 4.6m, and the depth of internal water accumulation was uneven, and there were sediments such as solidified sludge at the bottom of the tunnel.

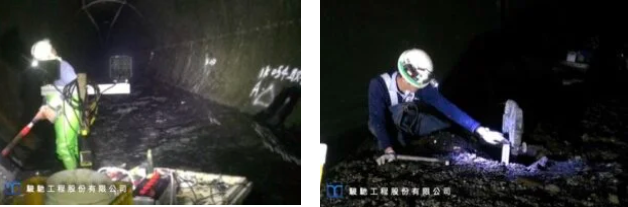

During the preliminary investigation, the engineers carried measuring equipment to conduct an on-site investigation by wading or rowing while wearing waterproof clothing.

During construction, scaffolding and floating platforms were used in combination. Although the site conditions were harsh, the work was carefully executed step by step according to planning and design.

—

5. RESULTS

After the grouting and surface repair work of each repair section was completed, the ground penetrating radar was again used to check the results. If insufficient filling was found, supplementary grouting was carried out immediately to ensure that the repair work was successfully completed.

After the repair and clean-up work was completed, inspection and maintenance of the sewers was carried out by professional technicians.This project had successfully eliminated environmental pollution and hidden land subsidence hazards.

—

Sewage Discharge Tunnel Leakage Detection And Restoration

將下載檔案寄至:

・More Construction Result Sharing

Contact us:+886 2769-2355

Copyright ©Jines Construction Co.,Ltd