GROUTING REINFORCEMENT & MUD-SPRAY TREATEMENT FOR AIRPORT TAXIWAY

Method for filling & strengthening ground beneath paving slabs

1. Project Background

Grouting Reinforcement : In the rainy season, an airport taxiway had serious mud spray from expansion joints and paving slab cracks.

In order to avoid hazards such as foundation hollowing and subsidence under the concrete paving and to maintain the international image of the airport, a professional company was commissioned to carry out planning and design for grouting reinforcement to ensure the safety of aircraft taking off and landing.

―

2. Solution

Because the airport was located in a subtropical climate zone, the annual rainfall was high, the soil under the taxiway is prone to softening after infiltration by surface water.

When the paving slab received the concentrated load of an aircraft’s wheels, the excited excess capillary water pressure sprayed the softened mud through the cracks of the paving slab up to the surface, causing localized hollowing under the paving slab.

However, because the airport taxiway could not be stopped for comprehensive repair, when planning the solution, the reinforcement method had to have the characteristics of flexible and rapid operation, short setting time of the filling material, and high compressive resistance and high flexural strength of the cured material.

―

3. Works Design

In order to define the location where the taxiway needed to be reinforced, and to evaluate the effectiveness of treatment, the Heavy Load Deflection Test on the section was carried out before and after grouting.

Selection of grouting material had to avoid large-scale damage to the concrete pavement in use and hydraulic fracturing of the ground below, while achieving the goals of high strength, fast curing, and quick operation.

After careful evaluation, it was decided to adopt a compressive strength greater than 30,000kPa and non-solvent micro-expansion PU resin grout with a curing time of about 60 minutes, with single-stage pressure grouting.

In order to avoid excessive lifting of the paving slab, after analysis, the grouting pressure was set to be no more than 500kPa, the deformation of the road slab no more than 3mm, and the real-time monitoring accuracy no less than ±0.5mm.

―

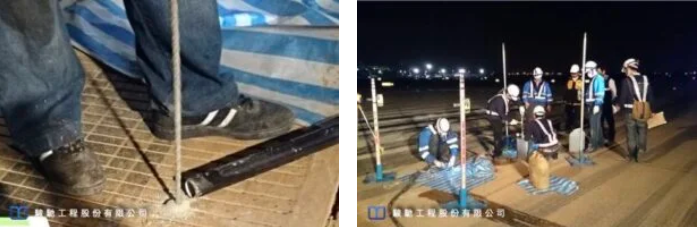

4. Works Process

The airport taxiway was in use, so maintenance could only be done within about a 3-hour period in the early morning when planes were grounded.All personnel, equipment, and materials during the works process were deployed on motor vehicles.

The concrete drilling and grouting process were used with dust removal and protection facilities at the same time to prevent any debris or grout from being scattered on the taxiway.

Each grouting hole was filled in accordance with the design requirements, and after the on-site supervisor confirmed that it was correct, it was immediately filled with special non-shrink cement, so aircraft could be taxied immediately after the airport opened in the morning.

―

5. Results

With good equipment and personnel deployment, this project successfully completed hundreds of grouting reinforcements and concrete crack repairs as required under the contract and within contract time.

Measuring the deflection of the corners of the grouted slabs to the center of the slabs by the testing unit using the Heavy Load Deflectometer, confirmed that the cavity under the paving slabs had been fully filled.

There was no further mud spraying up from the grouted area.Grouting reinforcement beneath the airport taxiway, and prevention and control of mud-spray were successfully achieved.

―

Airport Taxiway Grouting Reinforcement & Mud-Spray Treatment Technology

將下載檔案寄至:

・More Construction Result Sharing

Contact us:+886 2769-2355

Copyright ©Jines Construction Co.,Ltd