LEAK STOPPING METHOD FOR DEEP PIT EXCAVTION WITH A LARGE VOLUME WATER INRUSH.

Water inrush stop hot bitumen grouting technology for sedimentary soil layer excavation site.

1.Project Background

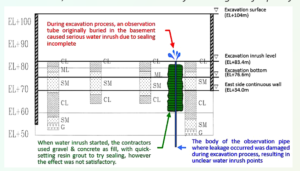

The site is adjacent to the MRT main line and elevated roads, and it was being constructed by the Top-Down method, with 6 basements.

When excavating the basement floor 4 during construction, an unknown buried pipe that was incompletely blocked in the base was encountered, resulting in serious water inrush at the excavation site.

In addition to urgently filling with gravel and pouring concrete covering at the water inrush area, the construction unit also dispatched workers to drill holes and inject foaming PU resin to try to plug the water gushing pipeline.

The effect of this attempted handling was unsatisfactory, and the phenomenon of water and sand influx was becoming more and more serious.The safety of surrounding MRT tunnels, elevated roads and neighboring houses was in jeopardy.

―

2. Solution

In order to avoid a serious disaster, the development unit urgently convened engineering experts to discuss countermeasures.

After on-site surveys, experts in the industry had seen that water and sand inrush were becoming more serious and the area of the base was too large for emergency water injection into the pit to ease the hollowing out of the ground.

Therefore, plugging of the leaking point was required to be completed within 24 hours. Only then could the safety of surrounding public facilities and neighboring houses be guaranteed.

―

3. Works Design

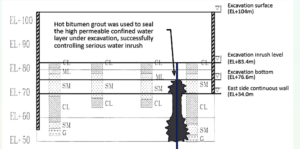

According to expert research and judgment, the pressurized water was coming from two confined water layers under the excavation surface, of which the lowest gravel layer was the least affected by the continuous wall barrier.

Because there were only 24 hours to deal with water and sand inrush hazards, our company decided to deploy a small modular one-diameter hot bitumen grouting piece of equipment specially used for basements and MRT tunnel water treatment, with electric drive drilling rigs for an emergency approach.

From the interface between the gravel layer and the clay layer, full-speed grouting was to be used to inject molten hot bitumen.

The steam pressure thus generated by the heat pump and the contact of hot bitumen with water would penetrate into the water gushing channels and rise up as water vapor, achieving the effect of blocking water and sand inrush at the same time.

―

4. Works Process

Because the grouting had to be carried out at basement level 4, the height of installation and operation of machinery and craning materials was limited, and it was difficult to mobilize workmen in a short time.

In addition, when the construction unit had carried out resin grouting earlier, the borehole penetrated the low-permeability clay layer, which caused the continuous expansion of the water inrush.

The basement level was partially flooded and the water outlet point was not clear.The unclear location and quantity of grouting, added to the uncertainty of the grouting effectiveness.This could only be determined by the experience of professional engineers.

―

5. Results

Through the company’s mobilization of experienced engineers to carry out emergency operations, only 5 holes were injected with hot bitumen grouting for this excavation water inrush. A plum blossom configuration was adopted.

As each hole was filled with hot bitumen grout, the water inrush obviously reduced.When the fifth hole was filled, all water inrush stopped.The excavation sedimentary soil layer was reached within 24 hours and the water inrush was stopped with hot bitumen grout, so rescue work was complete.

―

Water Inrush Stop Hot Bitumen Grouting Technology For Sedimentary Soil Layer Excavation Site

將下載檔案寄至:

・More Construction Result Sharing

Contact us:+886 2769-2355

Copyright ©Jines Construction Co.,Ltd