New Wu-chieh Tunnel

Water-Stop Grouting

The new Wu-chieh Tunnel is a 3.1km hydro-electric water transportation tunnel in Nan-tou County, Taiwan. Fractured zones under high hydrostatic pressure caused inflow rates up to 14m3/min during excavation.

Grouting methods included sodium silicate-cement and polyurethane resin, selected based on inflow rate variations along the tunnel. Water-proofing and consolidation was achieved.

New Yong-chun Tunnel

Hot Bitumen Grouting

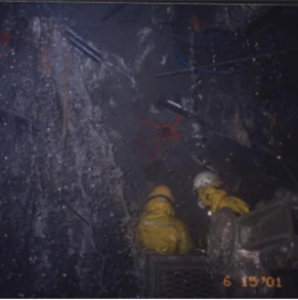

A fault zone caused this railway tunnel collapse due to severe water inflow during excavation; highest water pressure 50 bar (50mpa) and inflow rate 80m³/min.

Jines Co. used hot bitumen grouting, due to extreme situation. This was the first use in Taiwan. Water inflow was blocked and rock mass consolidated so excavation could continue.

Difficulties were resolved during the operation, giving it international visibility. Grouting work completed in June 2002.

Cang-feng Tunnel

Renovation

The Cang-feng tunnel on Ching-shan Power Plant Road has a total length of 251m. Due to long-term use and the impact of earthquakes, water seepage and lining cracking and peeling had occurred.

By drilling, fixed grouting pipes and tight seals, injecting cement and cement sand grout, in stages, the integrity and compression strength of the rock mass were improved.

Additionally, sealing joints, and repairing the lining surface layer, the tunnel successfully handled water leakage, extending its life.

Dai-kwang Tunnel

Repair Project

The Da-kwang Tunnel is a 3km water tunnel in central Taiwan. Started in Oct. 1999, finished on Apr. 30, 2000. It was affected by earthquakes, resulting in multiple cracks and faults in the tunnel lining

Repairs included crack lining, epoxy resin injection, cement grouting, and fractured rock polyurethane resin grouting of fractured rock mass.

In addition, rock anchors were installed and the surface was repaired with shotcrete. Tunnel resumed normal operation after repair work.

Wanta Songlin Hydroelectric Plant Expansion

Wanta Songlin Hydroelectric Plant Expansion–drilling and grouting works forthis project was from the tunnel excavation disaster section, water-stop consolidation, drilling and grouting.

The grouting (resin, cement, chemical),gas-seal grouting (polyurethane resin) and systematic backfill after completionof the lining.

Our company was involved in consolidation and curtain grouting.

Dajia River Power Plant

I-B Project

Before excavating the tunnel mouth, drilling and consolidation grouting were done at the Dajia River Power Plant Qingshan Branch Reconstruction project.

The disaster section was handled through various methods, and after lining, the company was involved in design, planning, and construction, including backfill and consolidation grouting.