1. What is Resin Grouting

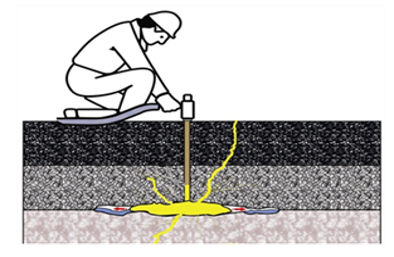

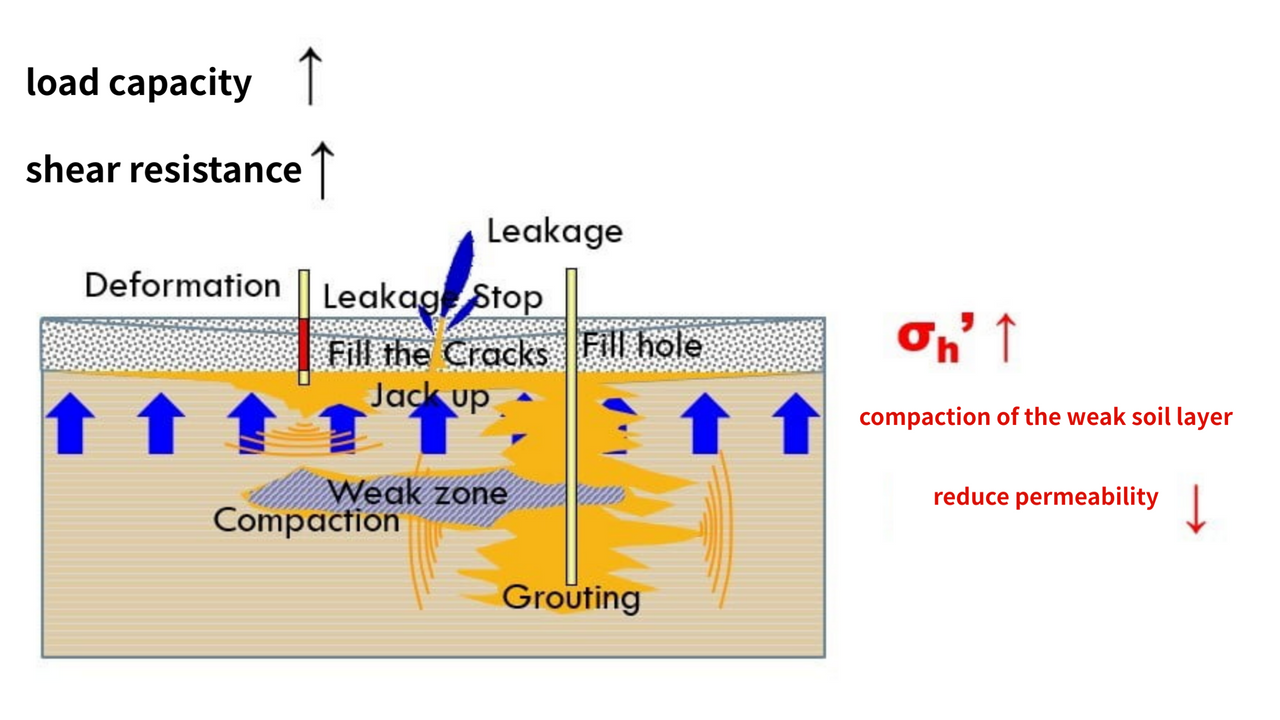

Resin Grouting (Shallow Resin Grouting Method) is a grouting technique used within 5 meters below the ground surface.

It involves the use of small-diameter drilling and small-caliber grouting pipes to inject suitable grout materials into the ground.

The aim is to achieve purposes such as raising pavements, structures, and buildings, sealing leaks, stopping water inrush, filling voids, improving ground conditions, and reducing local hydraulic conductivity of the soil.

During the grouting process, the annular space between the borehole and the grouting pipe needs to be sealed.

It is commonly performed using a 1-diameter or 1.5-diameter slurry pumping method, with grouting pressures ranging from P0 +1 to 35 kg/cm2. During the grouting operation, it is necessary to have a monitoring system in place to observe and prevent any potential secondary damage to structures.”

―

2-1. Resin Grouting Applications

Resin grouting is commonly applied within 2 meters below the ground surface for the following purposes:

- Lifting of pavements or road surfaces,

- Realignment of buildings,

- Sealing, waterproofing, and void filling of foundations,

Commonly used within a depth of 2m to 5m below the ground surface:

- Filling of voids or weak zones in the ground,

- Localized ground improvement (compaction grouting),

- Regional ground improvement (fracture grouting),

- Localized water sealing (injection grouting to fill water pathways or reduce local hydraulic conductivity of the soil).

―

2-2.Resin Grouting Applications (2)

Resin grouting methods for ground subsidence and hollowing treatment

―

3. Resin Grouting Advantages & Disadvantages

Advantages:

- The grouting unit is relatively small, and the equipment can be moved quickly and has fast turnaround.

- Suitable for construction in limited spaces.

- The construction process involves using electric drills or TY impact drills, with small borehole sections to minimize damage to the structure.

Disadvantages:

- The improvement depth is limited (typically not exceeding 5m) due to the energy of the drilling tools, such as electric drills, perforators, or TY impact drills.

- Some specialized permanent grouting materials may not be readily available in general construction material stores.

- Grouting monitoring requires experienced construction personnel to manage and control, as it involves high technical expertise.

―

4-1. Key Equipment for Resin Grouting

Drilling Machines:

- Handheld Electric Drill (can be used with up to 2m long drill bits)

- TY Drilling Machine (pneumatic)

- Percussion Drill

Grouting Machines:

- Resin Grouting Machine (Electric/Small flow rate)

- Pneumatic Grouting Machine (Pneumatic/Medium flow rate)

- Small Heat Pump (Used for hot asphalt injection)

- Piston Grouting Machine (Used for cement-based/bentonite-based grout materials)

―

4-2. Key Equipment for Resin Grouting(2)

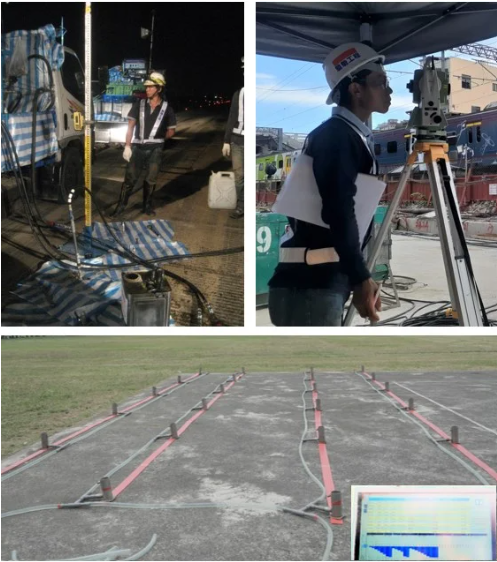

Monitoring Equipment:

- Laser Level (0.1mm accuracy)

- Automatic Theodolite

- Automated Monitoring Equipment

Other:

- Air Compressor

- Generator

- Cooling Water Pump

―

4-3. Materials Used in Resin Grouting

- Commonly used in Taiwan:

- Dual liquid non-expanding polyurethane resin (for filling and jacking)

- Dual liquid self-expanding polyurethane resin (jacking and water sealing)

- Silicate resin (for filling and jacking)

- Hot bitumen (for water inrush sealing and filling water pathways)

- Cement-based materials (for filling and intrusive ground improvement)

- Bentonite (+ cement) based materials (for filling and compaction ground improvement)

―

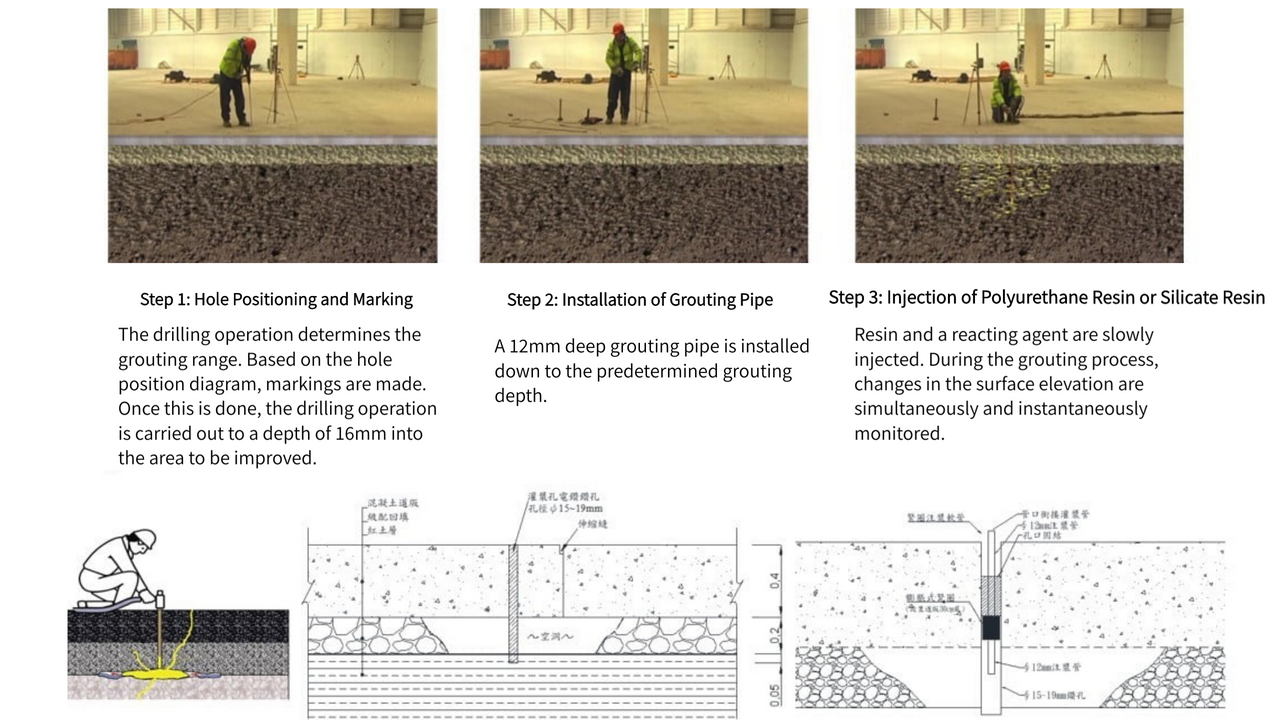

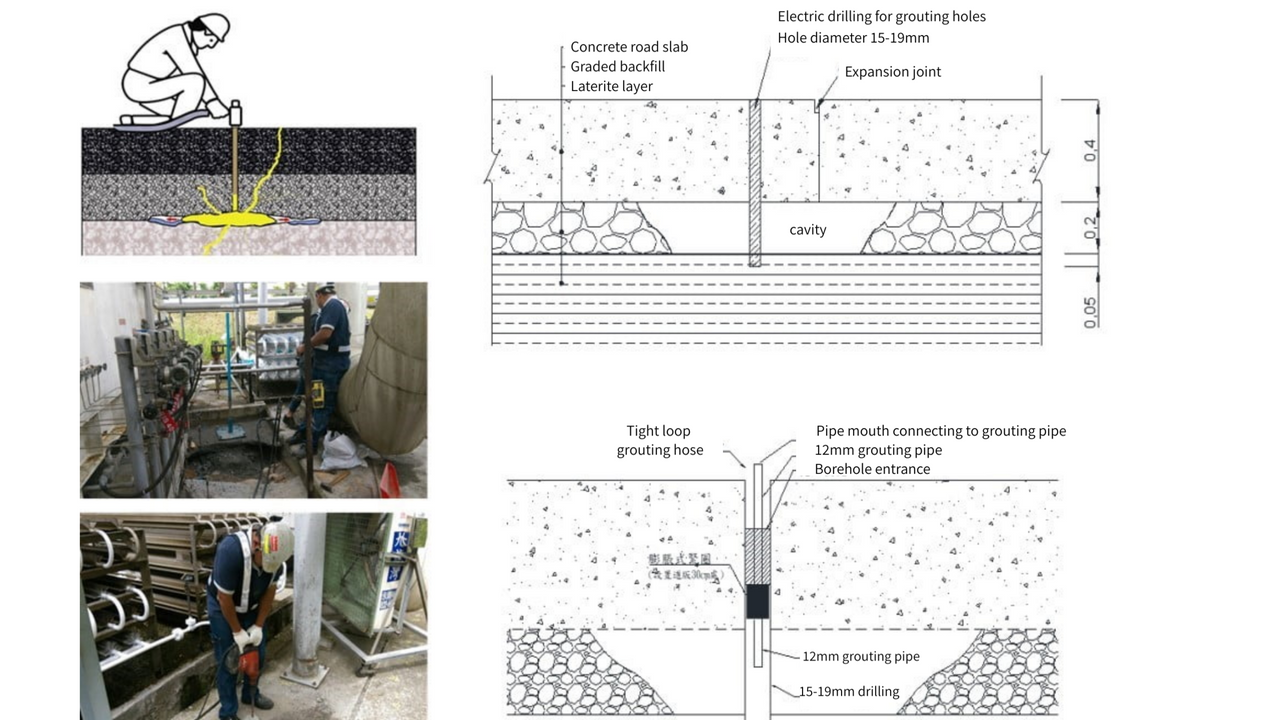

4-4. Resin Grouting Process (Depth ≤ 2m)

―

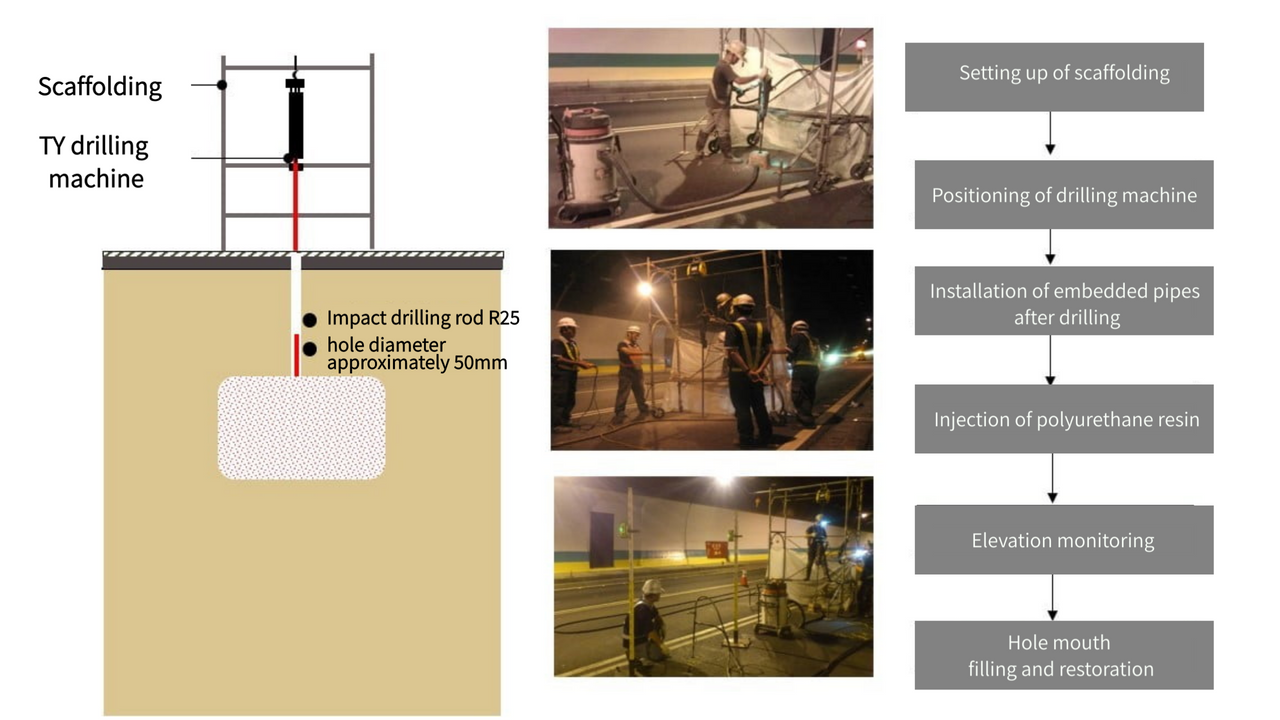

4-5. Resin Grouting Process (Depth ≤ 5m)

―

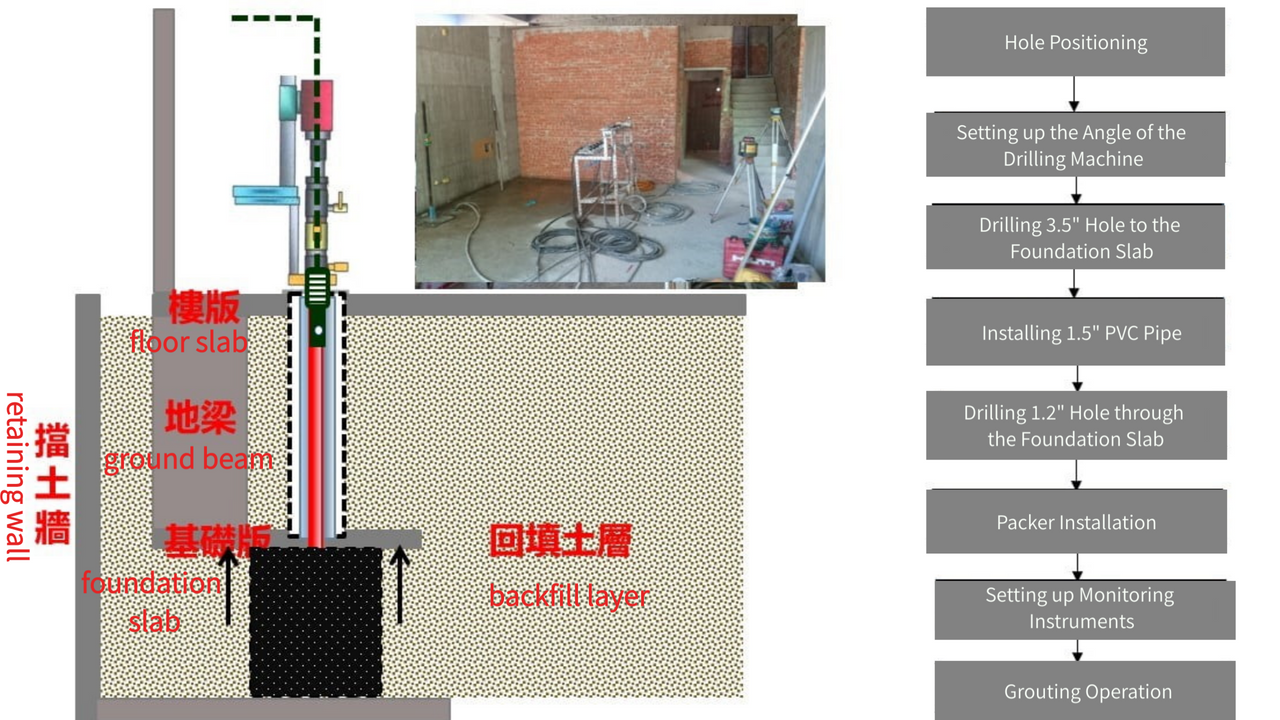

4-6. Resin Grouting Process (Single-Cycle Grouting, Depth ≤ 5m)

―

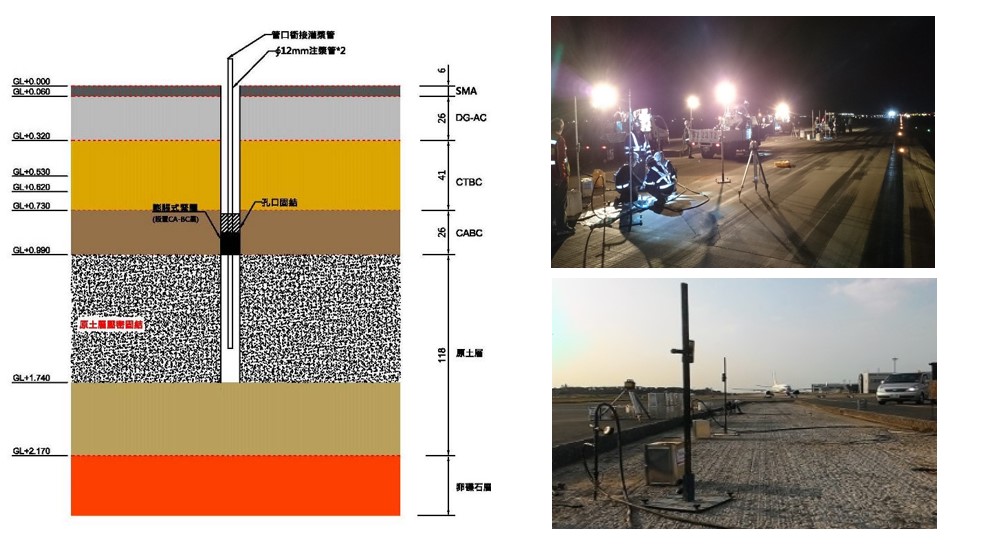

5-1. Case Study: Resin Grouting on Airport Taxiway

In alignment with airport operations and runway closure schedules, a resin grouting technique using polyurethane resin material was employed for rigid pavement lifting on the airport taxiway.

The operation was carried out during nighttime, allowing for immediate reopening of the runway for aircraft takeoff and landing. – Detailed case study sharing.

―

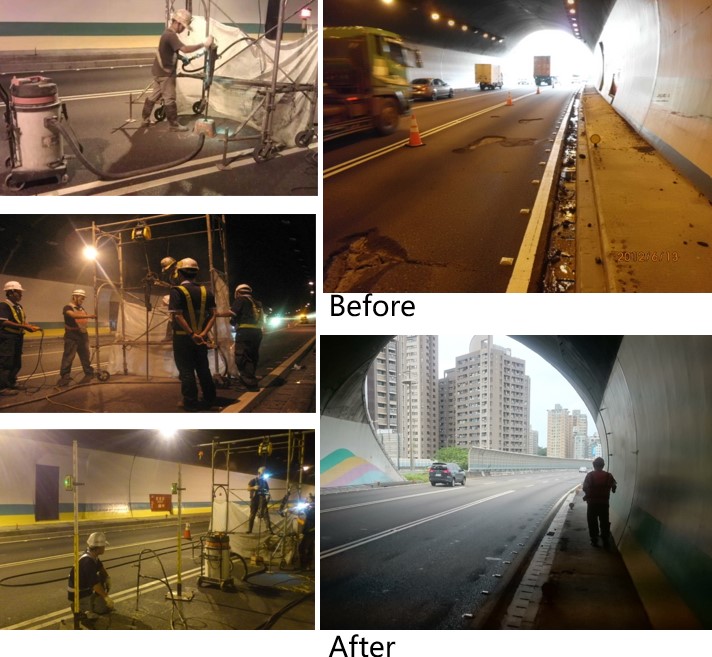

5-2 Case Study: Highway Base Reinforcement

―

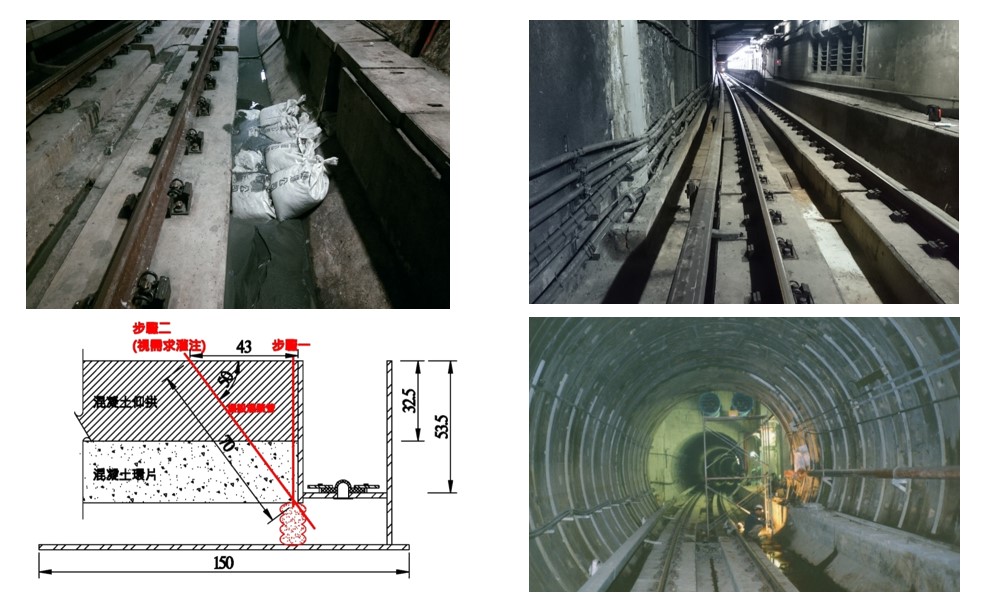

5-3. Case Study: Leakage Sealing and Reinforcement of TBM Tunnel Invert

―

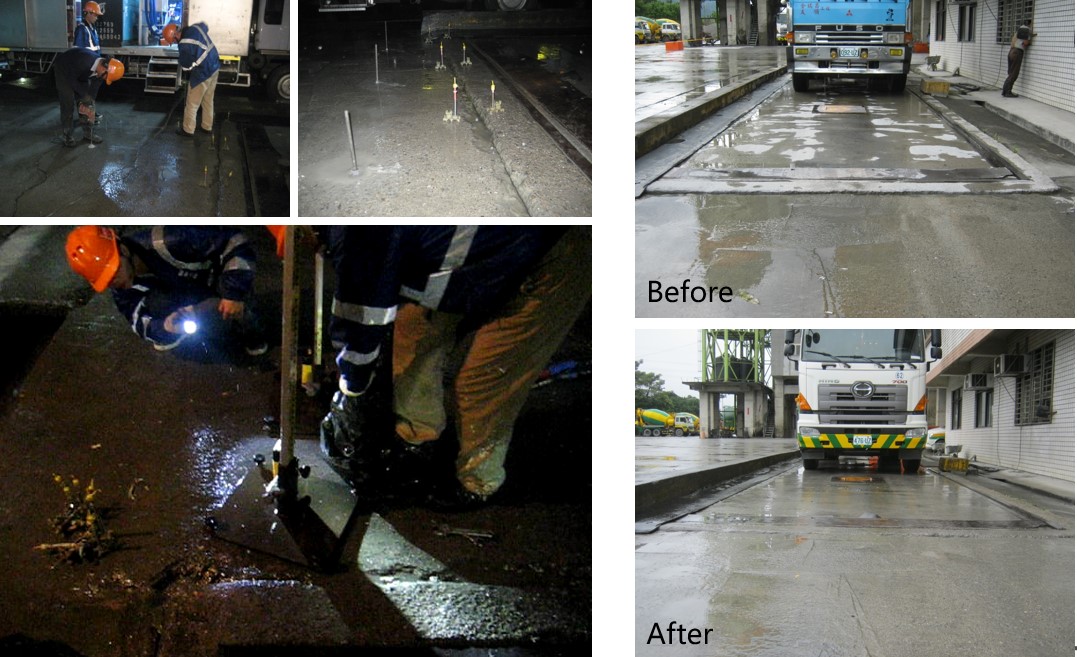

5-4. Case Study: Resin Grouting for Reinforcement of Rigid Pavement in Precast Concrete Plant

―

5-5. Case Study: Jacking & Reinforcement of Steel Mill Driveway Slabbing

―

5-6: Case Study: Precision Factory Floor Roof Reinforcement

―

5-7: Case Study: Building Roof Jacking (Direct Grout Jacking)

―

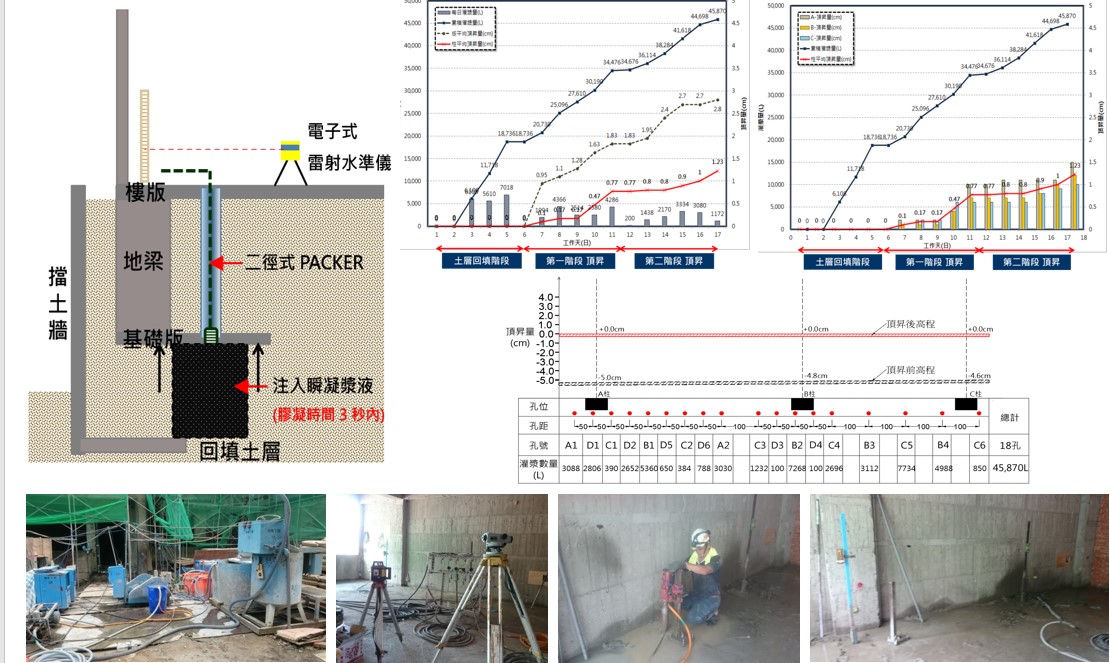

5-8. Case Study: Building Jacking & Reinforcement (Using Hydraulic Jack)

―

5-9: Case Study: Sealing Water Inrush in Raft Foundation (Hot Bitumen)

―

6. Selection of Resin Grouting Method:

- Selection of suitable grouting method based on project conditions

- Choosing an effective grouting method from the suitable options

- Selection of the most economical technique and materials among effective grouting methods

- Evaluation of feasibility within the project timeline targets

- Consulting with professional experts

―

・More Construction Result Sharing

Contact us:+886 2769-2355

Copyright ©Jines Construction Co.,Ltd