1. High-Pressure Injection Grouting : Clarifying the Concept

High-Pressure Injection Grouting Method: CCP – Small-Diameter High-Pressure Injection Pile (with Cement Slurry or Small Amount of Additives) Commonly used for:

- Assisting in water sealing of retaining structures (double-row design on the water-facing side/sand or interlayer formation considerations for effectiveness and verticality/counteracting soil pressures on retaining structures)

- Passive soil pressure enhancement within excavation face (overlap capability/counteracting soil pressures on retaining structures)

- Localized ground improvement for increased bearing capacity (considerations for sand or interlayer formation effectiveness)

LW – General Low-Pressure Cement Chemical Grouting (Portland Type I Cement + #3 Sodium Silicate) Commonly used for:

- Extensive geological improvement (delayed setting/time considerations/not suitable for saline, alkaline, or organic geological conditions)

- Water sealing of intermediate piles (rapid setting/short-term usage/not suitable for saline, alkaline, or organic geological conditions)

- Localized water sealing (rapid setting/short-term usage/not suitable for saline, alkaline, or organic geological conditions)

―

2.1 High-Pressure Injection Grouting Method

The high-pressure injection grouting method is a displacement technique that utilizes high-pressure water, compressed air, and high-pressure grout. It involves injecting them into the ground through small-diameter nozzles to cut through and affect the surrounding soil.

Taking advantage of the air density < water < grout characteristics, this method displaces the localized (or majority) of soil and pore water, allowing the grout to replace the evacuated voids and mix with the remaining soil. This process forms underground columnar consolidation bodies through displacement.

―

2.2 Advantages and Disadvantages of High-Pressure Injection Grouting Method

Advantages:

- Wide range of options available from various manufacturers, especially for small-diameter CCP.

- Applicable to a wide depth range.

- High overall strength achieved through high-pressure injection displacement and soil improvement.

- Easier control of grout distribution range.

Disadvantages:

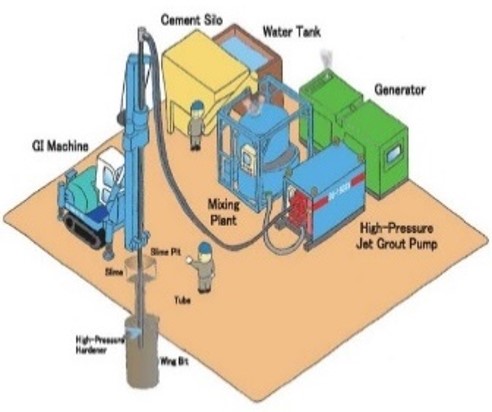

- Requires more grouting equipment and larger working space.

- Unsuitable for use within buildings or confined spaces due to high injection pressures.

- High injection pressures can cause surface uplift.

- Disposal of excavated material generated during the construction process may be challenging.

- Improper operation can pose risks of damaging underground structures.

- Less ideal formation effect in cohesive soil layers (better displacement effect in sandy soil layers).

―

2.3 Commonly Used High-Pressure Injection Grouting Methods in Taiwan

| Full Name | Chemical Churning Pile Method | Jumbo Special Pile Method | Jumbo-Jet Special Grout Method | Column-Jet Grout Method |

| Abbreviation | CCP Method | JSP Method | JSG Method | CJG Method |

| Commonly used pressure | 180~200kg/cm² | 180~200kg/cm² | 200kg/cm² | 400kg/cm² |

| Cement discharge volume | 25 L/分 | 25 L/分 | 50 L/分 | 140~180 L/分 |

| Drilling rod configuration | Single pipe | Double pipe | Double pipe | Triple pipe |

| Air | Not used | Depending on situation, may or may not be used | 7kgf/cm² | 7kgf/cm² |

| Forming diameter | 30~40cm | 60~80cm | 80~200cm | 80~200cm |

| Grout discharge volume | None | Small amount | Approximately 70% of original volume | Approximately 90%

of original volume |

| Works depth | 20m | 20m | 25m | 40m |

―

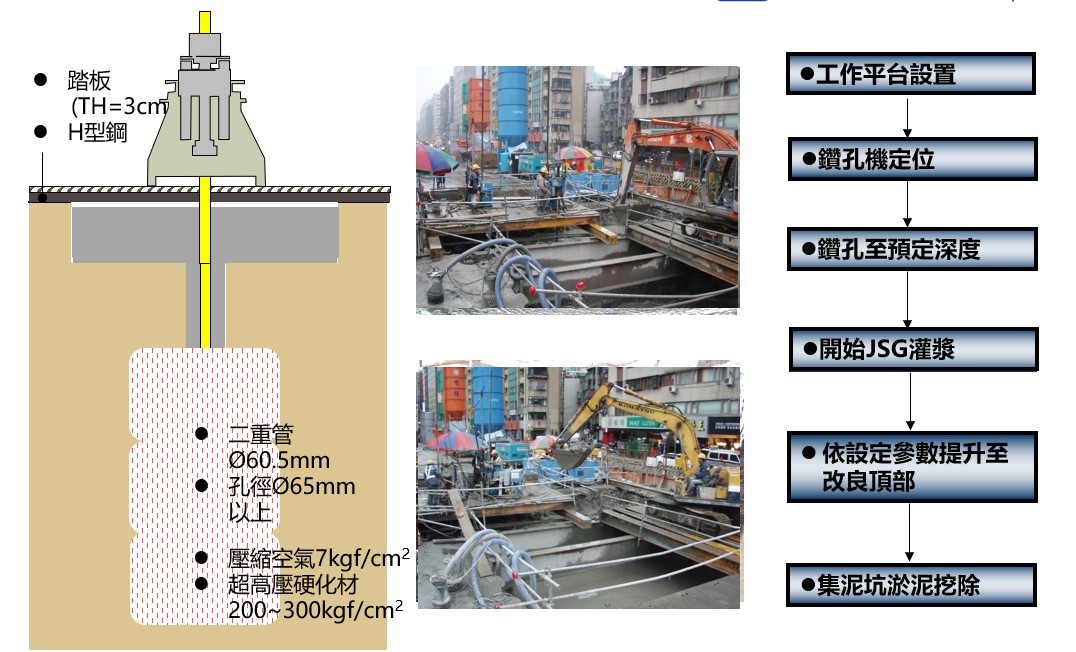

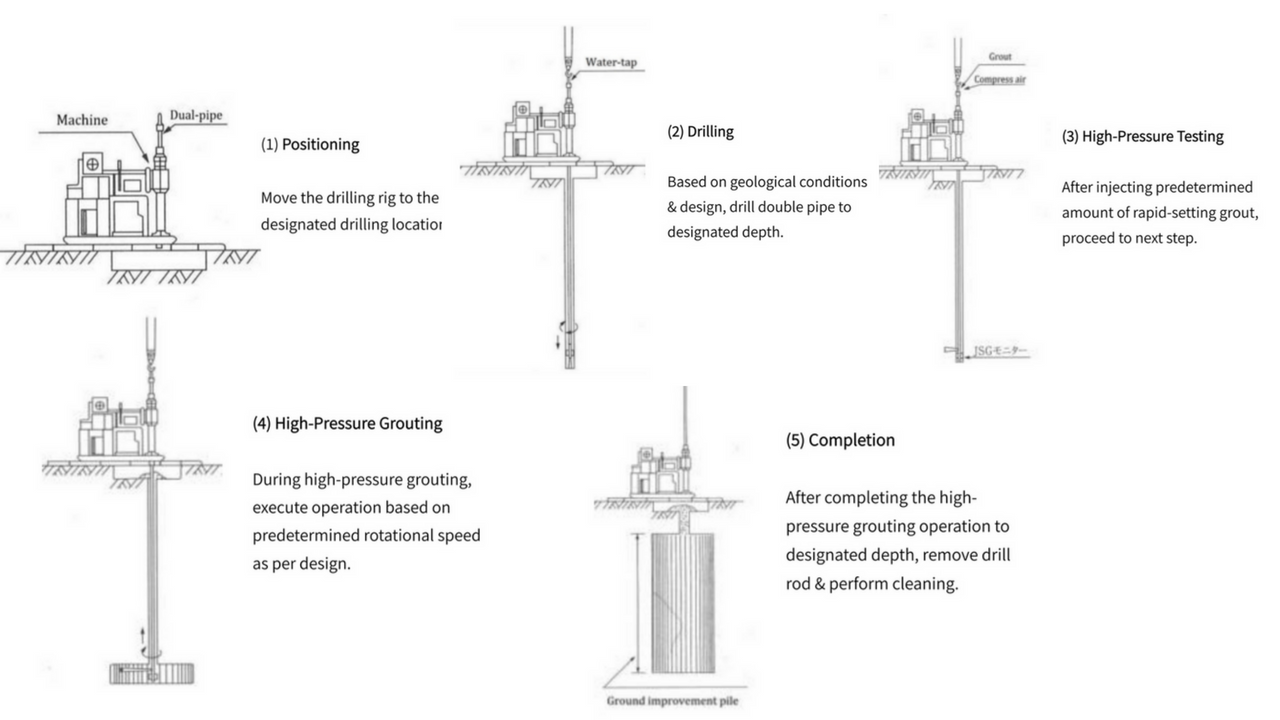

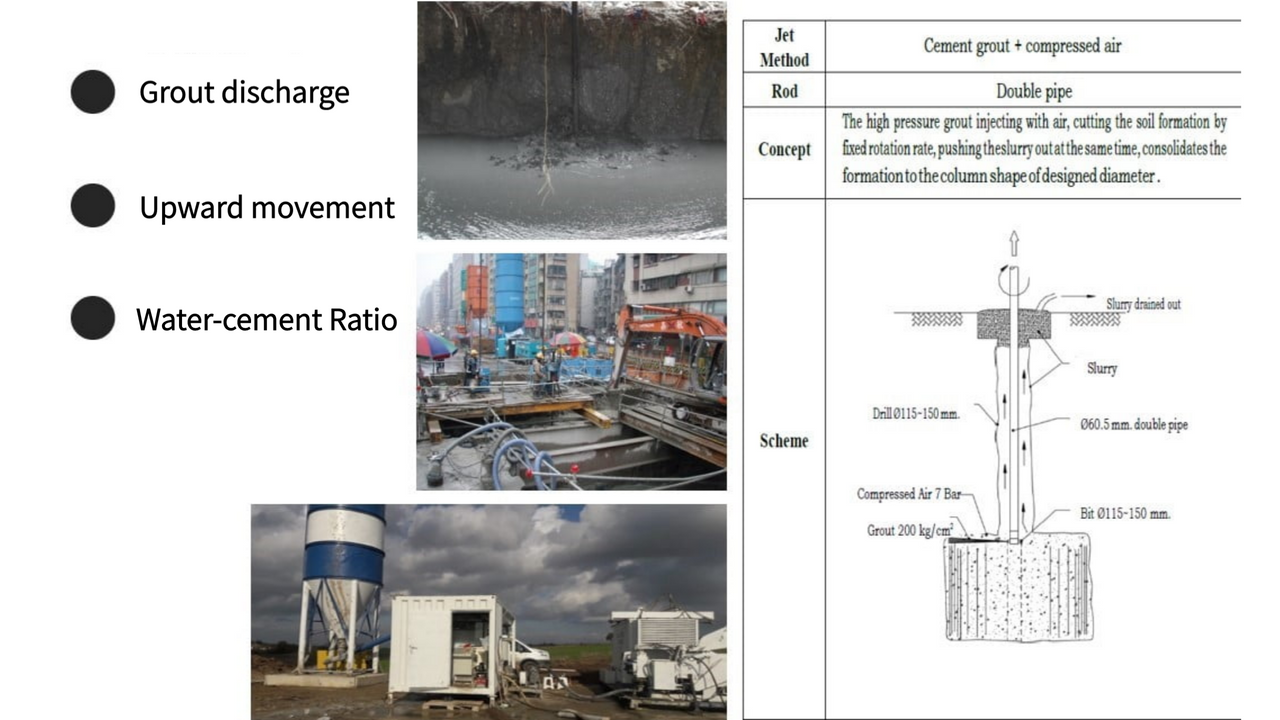

2.4 Operation Process Using JSG (Jumbo Jet Special Grouting) as an Example

―

2.5 Operation Process Using JSG (Jumbo Jet Special Grouting) as an Example

―

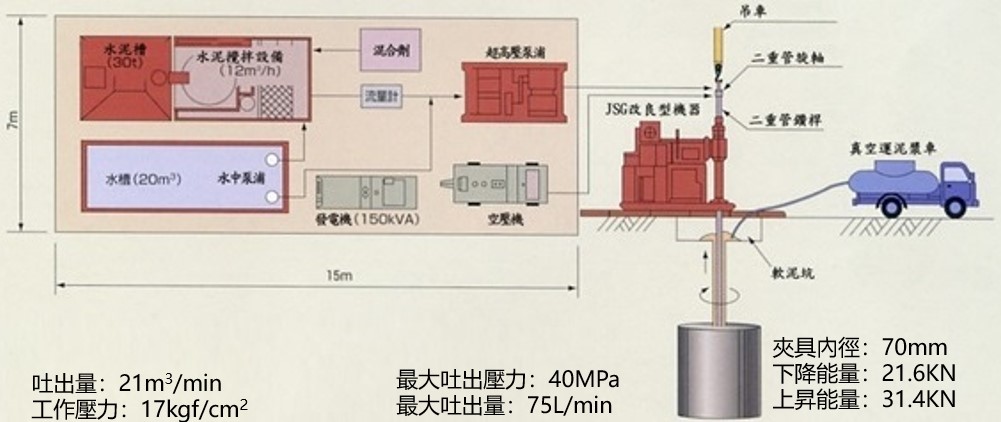

2.7 Equipment Used (Using JSG – Jumbo Jet Special Grouting – as an Example)

―

3. Key Factors for High-Pressure Injection Grouting Formation (Under the same conditions)

―

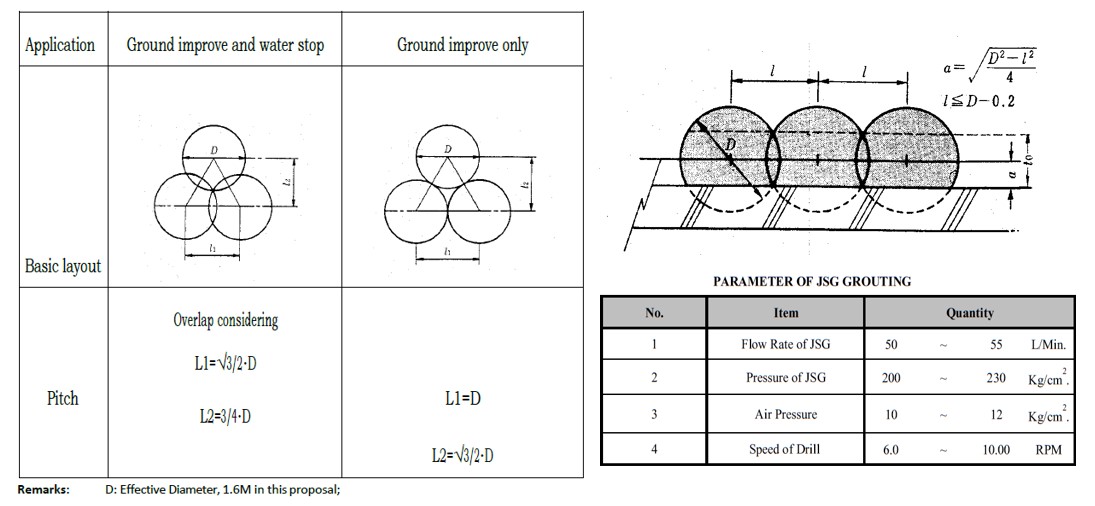

4. Design and configurati

―

5. Selection of Grouting Method:

- Selecting an appropriate method based on the project conditions

- Choosing an effective method among the suitable options

- Selecting the most cost-effective technology and materials among the effective methods

- Assessing whether the grouting objectives can be achieved within the specified timeframe

- Seeking advice from professional entities

―

・More Construction Result Sharing

Contact us:+886 2769-2355

Copyright ©Jines Construction Co.,Ltd