COFFERDAM PREVENTATIVE AND EMERGENCY WATER-STOP GROUTING

Water-stop grouting for preventative & emergency waterproofing in retaining pile joints during excavation

―

1. Project Background

The main bridge tower of a cross-river bridge had adopted steel pipe piles as the retaining structure. In order to prevent groundwater from inrush during excavation, management planned to conduct Double-Packer grouting between the excavation surface and the underlying bedrock at each joint on the outer side of the piles. Additionally, self-expanding polyurethane resin would be injected into the gaps at the pile joints to enhance waterproofing capabilities for excavation.

―

2. Solution

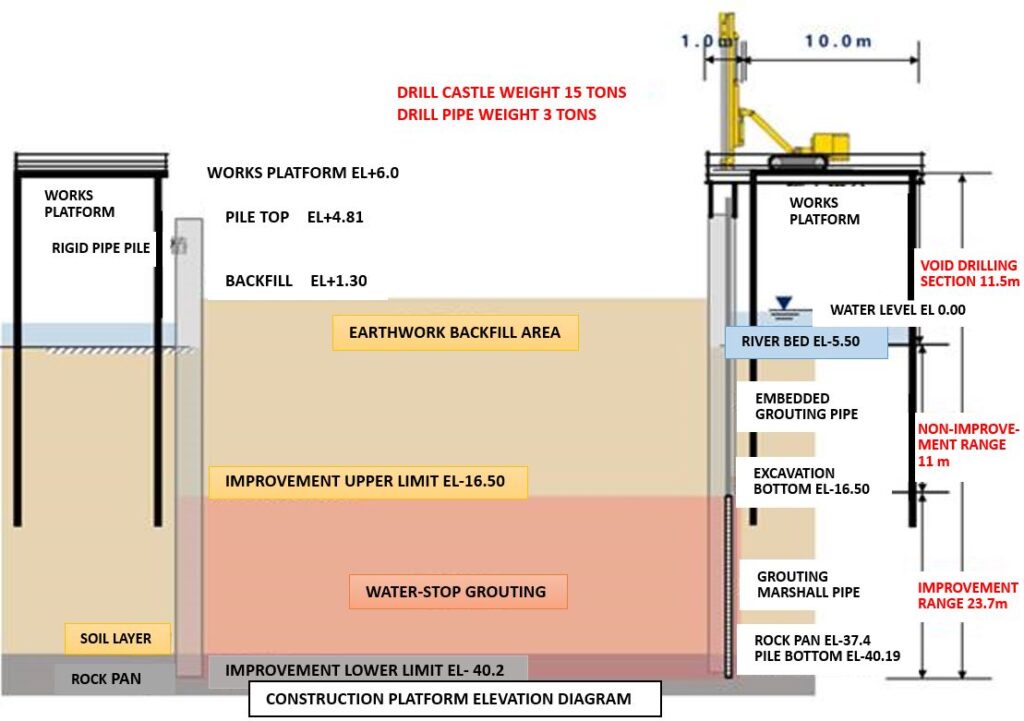

The construction area of the main bridge tower ranged from the riverbed surface (EL-5.5m) to the underlying bedrock surface (EL-37.4m). The predominant strata consisted of highly permeable layers such as silty clay with silt, sandy silt, and gravel layers. Approximately 6.8m of fill material had been backfilled above the original riverbed to serve as the working surface.

To reduce the risk of groundwater seepage during excavation, grouting was be conducted beforehand on the outer layers of the pile joints from the excavation bottom (EL-16.5m) to the bottom of the steel pipe piles (EL-40.2m). The relevant operational plan was as follows:

- For pile depths where penetration into the underlying rock reached 3m, grouting depth was to match that of the pile base without requiring additional depth.

- Marshall pipes made of PVC material, equipped with reverse stop valves, to be embedded below the excavation surface for grout injection.

- Due to the proximity of the construction area at the river mouth to the sea, grouting to utilize SSA low-sodium sodium silicate chemical grout, known for its resistance to salt and alkali.

- Grouting to begin with CB grout to fill and compact weak zones in the strata, followed by injection of SSA chemical grout at the same locations to reinforce the strata effectively and reduce its permeability coefficient simultaneously.

―

3. EMERGENCY WATER-STOP

According to the original design, SSA chemical grout was injected, followed by the implementation of self-expanding polyurethane resin filling at the pile joints, before commencing the excavation of the foundation. However, deviations in the verticality of the piles and other factors such as detachment resulted in several instances of water seepage between the riverbed and the excavation surface during the excavation process.

As exterior grouting of the outer layers was not previously conducted within this elevation, to facilitate the excavation work smoothly, the management urgently commissioned a professional team to perform instant-setting grouting using the double-packer method on the outer side of the seepage locations.

Additionally, preparations were made to install a circle of steel sheet piles outside the sheet pile retaining structure. Original soil to be backfilled between the two structures, and cement jet grouting to be carried out to attempt to seal off the inrush of river water and groundwater into the excavation site, employing a dual-layer retaining structure and ground improvement grouting in combination.

―

4. Works Process & Results

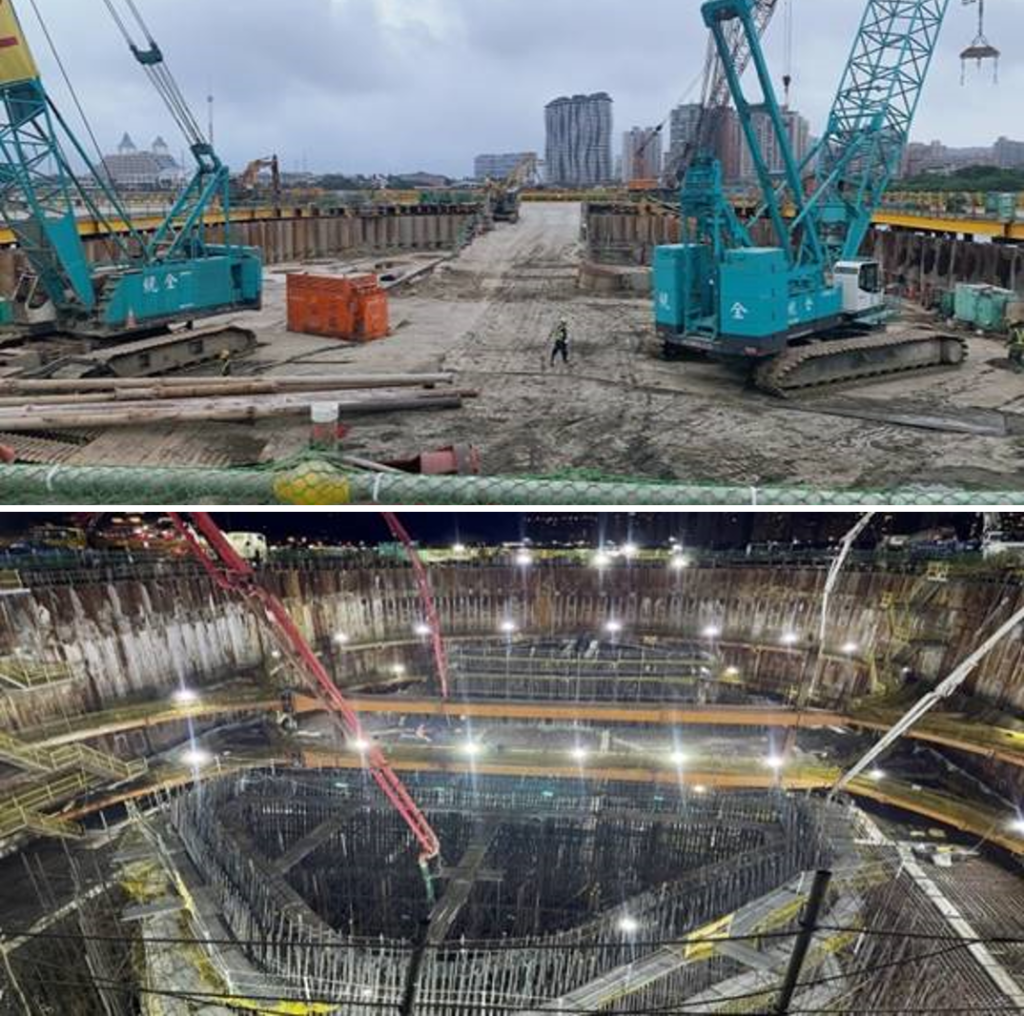

As the construction area provided ample space, the execution of various emergency additional tasks was relatively smooth. However, due to the disturbance of surrounding strata and the complex permeation pathways within the backfilled soil of the double-layer retaining facilities, sealing one leakage point often lead to the emergence of others nearby. Moreover, as excavation depth increased, new seepage points may arise. The grouting team had to remain on standby throughout the excavation process, ensuring that they work without delays in project schedule.

―

5. RESULTS

With the joint efforts of various construction teams, the excavation work within the cofferdam proceeded in an orderly manner. Upon reaching the bottom of the excavation, no water seepage occurred, indicating the effective water-stop performance of the double-packer grouting at the sheet pile joints. Following this, management expedited the pouring of PC layer columns overnight, treated the pile heads, bound the bridge foundation steel bars, and poured concrete.

As a result, it was confirmed that the lower part of the main bridge tower achieved the expected goals, successfully completing the preventative and emergency grouting work for cofferdam construction.

―

・More Construction Result Sharing

Contact us:+886 2769-2355