GROUND IMPROVEMENT BY ARTIFICIAL GROUND FREEZING FOR TBM TUNNEL DEFORMATION AND INRUSH CONTROL

Application of Brine Circulation Ground Freezing for Emergency Stabilization of TBM Tunnels in Tropical Regions

―

1. Project Background

During construction of a TBM tunnel in Thailand, settlement and displacement occurred at the connection between a shaft and the tunnel, resulting in groundwater and sand inrush into the underground space and causing tunnel collapse. To protect surface structures, shallow box culverts, and various utility pipelines, the contractor carried out emergency backfilling of the collapsed area and continued ground improvement grouting at and around the collapse location; however, the results were not satisfactory.

After consulting experts with experience in ground improvement and emergency stabilization, and in response to the challenging conditions of this project, the artificial ground freezing method was selected to stabilize and seal the ground. Jines Construction (Thailand) Co., Ltd. was responsible for technical integration and execution of the works.

―

2. Solution

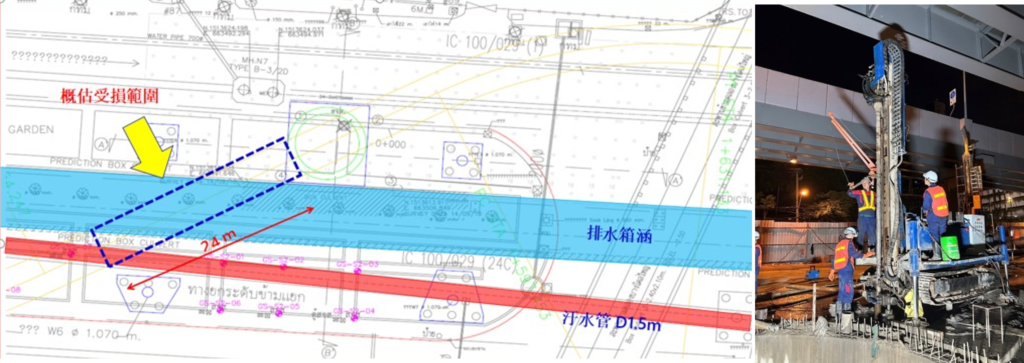

This incident occurred at a depth of approximately GL-26.0m to GL-30.5m below the urban surface. The ground surface included elevated bridges, major roads, residential buildings, and high-voltage transmission towers, while underground utilities included shallow buried drainage box culverts, sewer pipelines, and various public utility lines. In addition, underground obstructions such as sheet piles were present around the shaft. The site was also located near the Chao Phraya River, with abundant groundwater exhibiting flowing characteristics.

After evaluating all influencing factors, the artificial ground freezing method was selected for emergency stabilization, and the solution was implemented as follows:

(1) site investigation, collection of existing data, and supplementary drilling;

(2) analysis of ground conditions and design of the freezing curtain, freezing holes, and field monitoring system;

(3) selection of freezing equipment and design and arrangement of the refrigeration plant;

(4) on-site drilling, trench excavation, and pipeline installation;

(5) ground freezing operations with real-time monitoring and feedback analysis;

(6) tunnel emergency repair, continuous monitoring, and emergency response;

(7) maintenance of frozen conditions, termination of freezing, and dismantling of the refrigeration plant;

(8) removal and grouting of freezing pipes, thaw settlement protection and monitoring, structural repair, and site restoration.

―

3. WORKS DESIGN

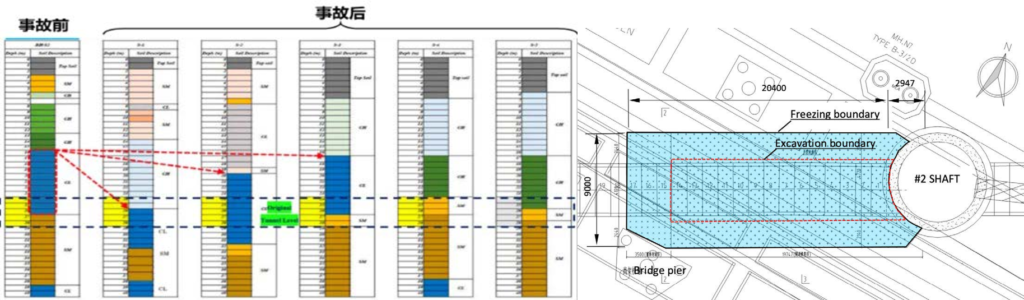

The collapsed section of the TBM tunnel was approximately 16.9 m in length. The original tunnel design centerline was at GL-26.55 m, and the maximum depth after collapse reached approximately GL-31.50 m. The soil strata consisted of silty clay from GL-16.0 m to GL-27.0 m, and silty fine sand from GL-27.0 m to GL-38.0 m.

To ensure protection of affected structures and safety during subsequent repair works using the artificial ground freezing method, the key design considerations were as follows:

(1) five geological investigation boreholes were drilled at the incident location to compare soil stratification and disturbance conditions before and after the collapse;

(2) a brine freezing method (calcium chloride brine, specific gravity 1.26–1.27) was adopted, combined with an optimized design of “long freezing pipe inlet and short freezing pipe outlet” to concentrate freezing energy within the repair zone;

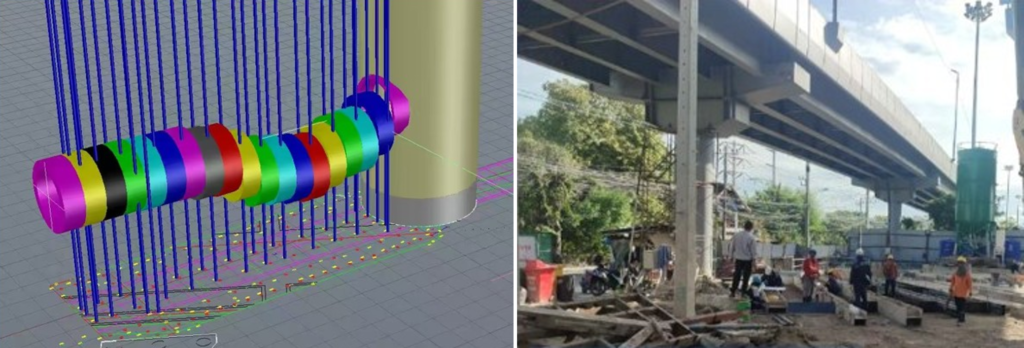

(3) the freezing zone measured 20.4 m in length, 9.0 m in width, and 35.51 m in height, with additional freezing zones of 2.95 m and 1.55 m in length adjacent to the shaft. The effective frozen wall thickness was 2.14 m, with a bottom protection layer thickness of 4.70 m. A total of 108 freezing pipes with an outer diameter of 127 mm were installed;

(4) freezing pipes were symmetrically arranged along the tunnel axis in six rows, with row spacing of 1.7 m and hole spacing of 1.75 m. The maximum drilling depth extended 5 m below the tunnel segment invert;

(5) the design strength of frozen soil at -10°C included a minimum unconfined compressive strength of 4.0 MPa, minimum flexural tensile strength of 2.0 MPa, and minimum shear strength of 1.5 MPa;

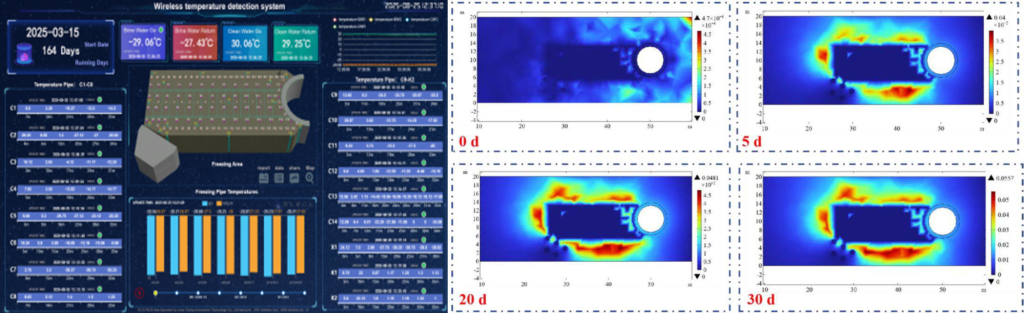

(6) fifteen temperature monitoring holes were installed within the freezing zone, and temperature sensors were installed in each freezing pipe circuit to automatically monitor frozen ground development and equipment performance, with feedback analysis implemented;

(7) the ground freezing system was maintained in operation until tunnel structural repairs were completed and the structure achieved at least 60% of its design strength, after which freezing was terminated and brine heating circulation was used to thaw the frozen ground;

(8) the refrigeration plant and pipelines were dismantled, freezing pipes were extracted and backfilled with concrete, and enhanced monitoring of ground, box culverts, and protected structures was carried out during thawing and removal of freezing equipment to control settlement and deformation.

―

4. Works Process

As Thailand is a tropical country, the high temperatures of the air, ground, and groundwater presented significant challenges for implementation of the artificial ground freezing method. In addition, the construction site was located beneath an elevated bridge, with numerous and complex surface and underground structures requiring protection.

During construction, normal traffic flow on the elevated bridge and adjacent surface roads had to be maintained, further increasing execution difficulty. To address these conditions, this project adopted advanced localized freezing concentration technology, integrated with automated monitoring and feedback, and implemented a PSO algorithm–based digital twin model for real-time safety analysis. This approach enabled precise control of site conditions and ensured the safety of tunnel repair works and all protected structures.

―

5. RESULTS

Through the innovative localized freezing technique using long and short freezing pipes, combined with safety analysis based on monitoring data feedback and a digital twin model, this project achieved effective earth-retaining and water-sealing performance with a longitudinal effective frozen length of 3.5 m at the tunnel collapse sealing section, an effective frozen thickness of 5.0 m above and below the tunnel, and an effective frozen thickness of 2.4 m on both sides of the tunnel.

Monitoring data during construction indicated that the maximum frost heave deformation of the shallow box culvert was only 8.29 mm, while the overall maximum ground frost heave was approximately 5.57 cm and was concentrated around the freezing zone.

These values met the low-disturbance requirements of the artificial ground freezing method and did not cause differential deformation affecting the ground surface, shallow structures, or the damaged TBM tunnel. The ground improvement works using artificial ground freezing for control of deformation and inrush in the TBM tunnel were successfully completed.

―

・More Construction Result Sharing

Contact us:+886 2769-2355