HIGH-PRECISION AUTOMATIC ELEVATION MONITORING SYSTEM INTRODUCTION

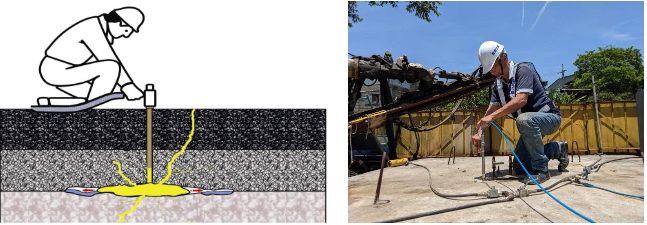

The best matching equipment for grout jacking technology

1. Project Background

While railways, airport runways, expressways, industrial plants, etc. are in operation, if structural slabs are deformed due to stratum hollowing or compaction subsidence, this may cause serious problems such as danger to public, traffic paralysis or production interruption.

When encountering the above situation, it is often necessary to carry out stratum reinforcement and structural jacking work. Because public transportation and industrial production cannot be interrupted, such site improvement work is often carried out at night.

In addition, the jacking elevation must be precisely controlled during the construction process to avoid secondary damage to the original structure.

―

2. Solution

The existing elevation monitoring methods mostly use optical equipment such as laser level and theodolite for measurements. Because this type of equipment requires special personnel to operate, it requires high visibility conditions and light.

This often causes problems such as high manpower demand, inability to fully deploy points for observation, and slow response time.

In response to this kind of demand, instrument manufacturers have also developed equipment for multi-point continuous observation using the principle of connected pipes, but they are not widely used due to factors such as high prices and the fact that signal lines may affect grouting operations.

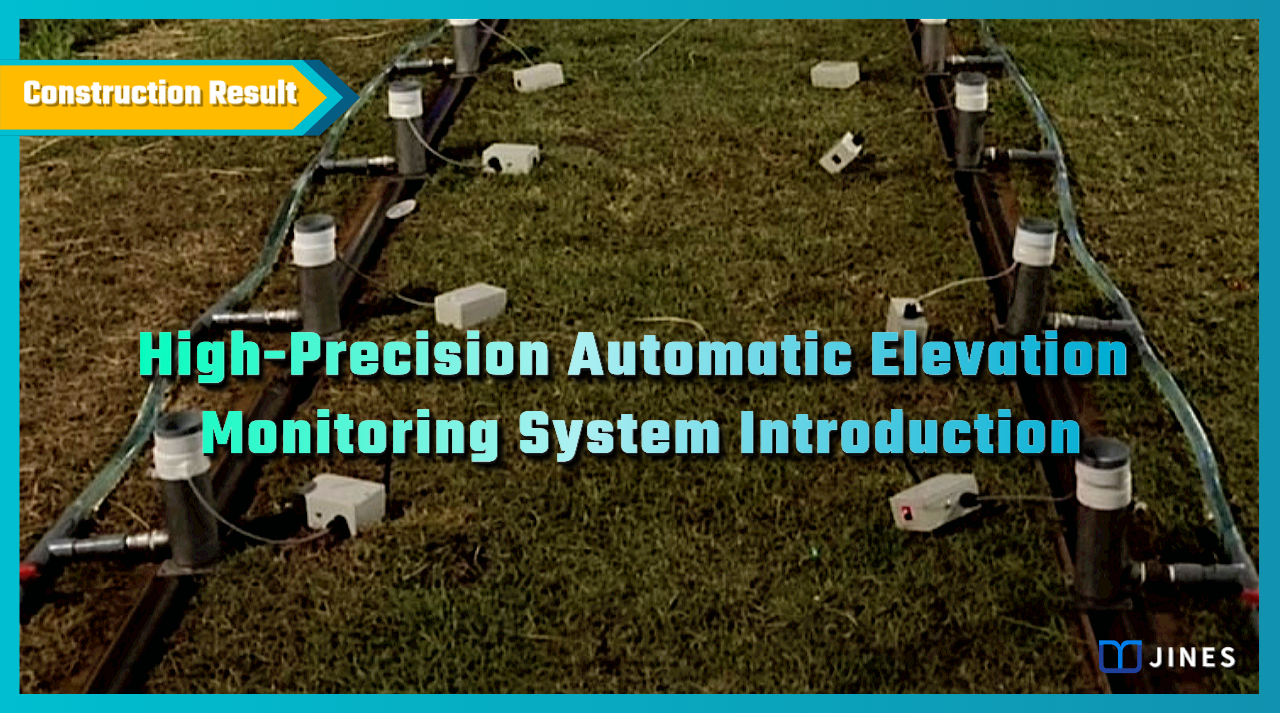

In order to solve the above problems, our company specially developed a high-precision automatic elevation monitoring system that is easy to move, does not need to configure signal lines, and can be “plug-and-played” on site.

―

3. System Design

The traditional interconnected tubular elevation monitoring equipment mostly uses sensors such as high-precision load cells, displacement meters, optical fibers and differential pressure meters to measure the liquid level change in the monitoring point module.

If the equipment is often moved, it is easily damaged, so it is more suitable for fixed position monitoring applications.

In order to meet the needs of flexible and mobile site improvement grouting monitoring, the newly developed equipment retains the connecting pipe structure.

It also uses fixed high-precision ultrasonic sensors with a wireless transmission design between nodes.

This achieves the advantages of convenient equipment movement and no need to connect multiple power lines and signal lines on site.

―

4. Development Process

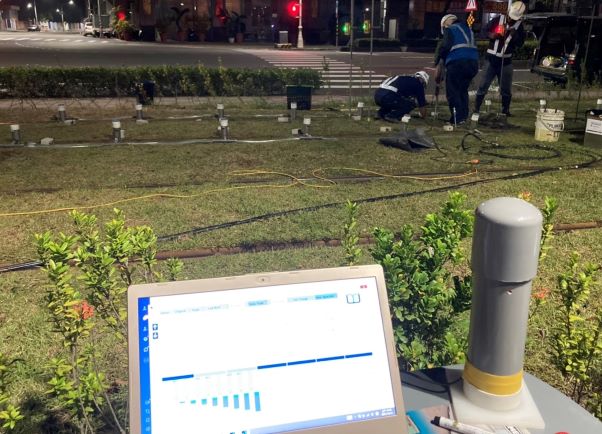

In order to match the measurement accuracy that can be achieved by optical equipment, the company specially commissioned foreign professional consultants to introduce high-precision ultrasonic sensors, which are equipped with a near-end single-chip processor and built-in firmware program to interpret the signals read by the sensor code.

After noise removal and numerical calculation, the near-end wireless transmission equipment sends the data to the receiving end for analysis, and presents it on the man-machine interface and records the physical quantities of each node in synch.

Because of the use of an independent near-end operating system, in order to improve the time use of its own power supply, it adopts a low-power wireless transmission design.

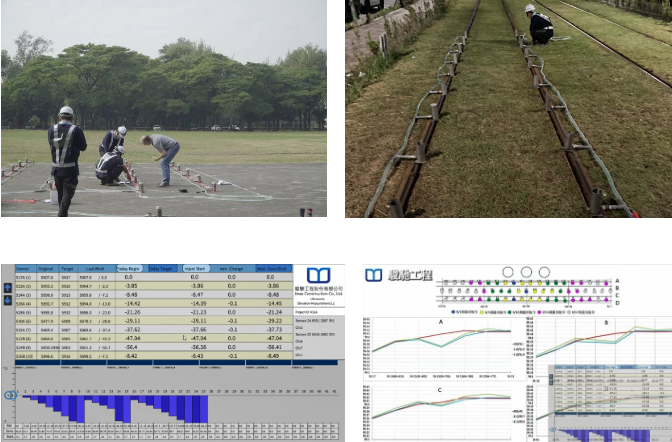

After the actual test, the system can be arbitrarily arranged in the site according to the requirements within a radius of 50m from the receiving end, so as to achieve the goal of plug-and-play and comprehensive monitoring.

After the equipment was developed, it was tested in the laboratory, in the field and in actual engineering. The response results are consistent in comparison with optical instruments.

―

5. Application Results

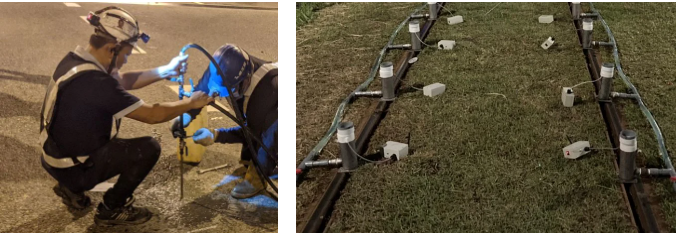

In order to avoid affecting the daytime traffic and normal functioning of roads, airport runways, expressways, and precision workshops, nighttime construction is often used with quick-setting grout materials.

For example, a non-solvent-based rigid resin that can cure within 30 seconds and has a compressive strength of more than 40 MPa, which can be jacked from under the structural slab and filled with compaction grouting.

Because the curing time of such materials is fast, if the elevation cannot be monitored immediately during pouring, it may cause great losses and a problem to the society.

The real-time monitoring target could be achieved through the high-precision automatic elevation monitoring system. So, excessive jacking and out-of-position deformation of the concrete slabs, resulting in damage and track deformation caused by excessive angular variables was avoided.

This ensured that the grouting jacking work met the design and planning requirements.

―

Mountain Tunnel Expansion Excavation Section Grouting Reinforcement

將下載檔案寄至:

・More Construction Result Sharing

Contact us:+886 2769-2355

Copyright ©Jines Construction Co.,Ltd