TBM LAUNCH SITE SITE GEOLOGICAL IMPROVEMENT BY HIGH PRESSURE JET PILES

Geological improvement technology of TBM launch/arrival sites

1. Project Background

A large drainage tunnel in a metropolitan area with an outer diameter of 6.0m was constructed using the TBM method. One of the pumping stations was constructed with a work-shaft with an outer diameter of 17.0m.

The center point of the TBM launch site of this work-shaft was as deep as GL-32.58m. In addition, the surrounding area of the foundation was close to drainage channels and ponds, and the groundwater level was extremely high.

The geological improvement at the launch site of the TBM and the stratum water stop work had become key elements for the smooth progress of the project.

―

―

2. Solution

According to the geological survey data of the foundation, the upper half of the stratum around the launch site was a medium compact silty fine sand layer, and the lower half was a hard clay layer.

Because of the great differences in geological conditions, the effectiveness of geological improvement at the launch site was very important. When planning, according to the construction method suitable for the project conditions, two schemes of superimposed high-pressure jet grouting and low-pressure dual-pipe horizontal grouting were drawn up for comparison and selection.

After careful evaluation, due to the fact that the foundation did not have the problem of shallow pipeline migration, and the contractor’s requirements for construction progress and other factors, the high-pressure jet piles that can be used on the surface and chemical water-stop grouting were finally chosen to be used to achieve water-stop reinforcement in the strata.

―

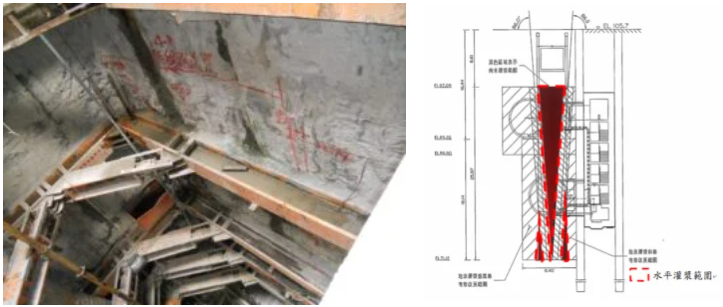

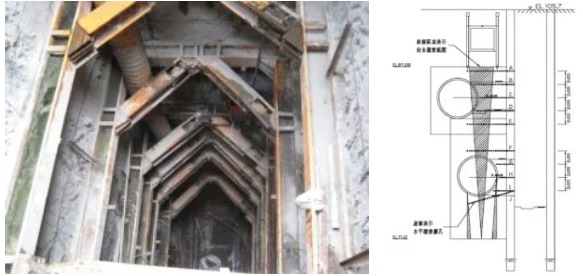

3. Works Design

According to analysis of project conditions, the geological area where improvement needed to be carried out, had a width of 12.0m, a length of 6.0m, and an improvement depth of 10.5m (GL-27.08m~ GL-37.58m).

The semi-replacement reinforced JSG grouting method with an effective pile diameter of 120cm was to be adopted. The spacing of grouting holes was to be 90cm~100cm, and the overlapping range of 20cm~30cm, and a total of 98 holes.

In order to avoid a permeable path between the piles caused by uncertain factors, 14 chemical grouting holes with a spacing of 1.8m~2.5m to be set up in the geological improvement range, and the holes to be paired with the retarded SSA chemical grout to seal the waterway.

In addition, at the junction of the improvement area and the break-through face, an emergency water-stop grouting plan using dual-pipe was formulated. The grouting depth was set from 1.5m below the improvement range to 1.0m above the improvement range.

In case of water leakage during the break-through face removal process, reverse grouting could be performed immediately to water-stop.

―

4. Works Process

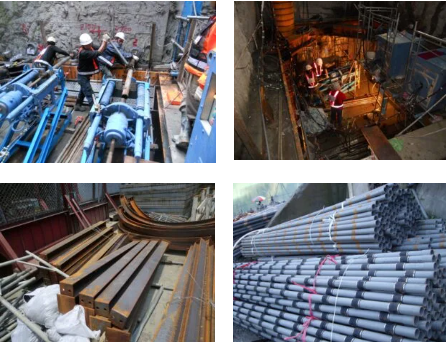

In order to meet the requirements of the project schedule, a self-propelled drilling rig and the KH-120 hydraulic rotary drilling rig were used for simultaneous operation during construction, and reinforced JSG high-pressure jet grouting was carried out with a straight special dual-pipe.

The injection volume of grout was 50~60L/min, the injection pressure was 21000~24000kPa, the enhanced air pressure was 1000~1200kPa, and the rotary spray speed was 6~10rpm.

Because the strata conditions of the improvement range were quite different, the injection setting of each hole needed to be determined by reference to the grout flow rate and mud discharge conditions after water tests and irrigation tests by rotary jet.

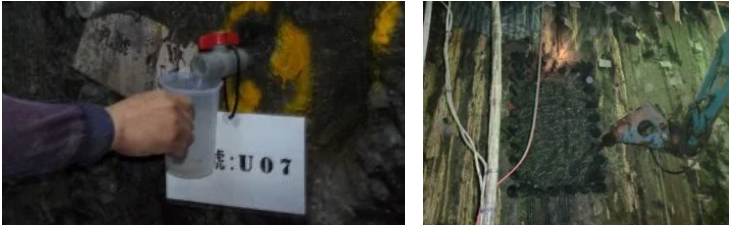

After each piece of grouting work was completed, 7 water-stop valves were set up on the break-through face to conduct water penetration tests at different depths in the improvement area to determine the water-stop reinforcement effect of high-pressure jet grouting.

―

5. Results

After grouting according to the design, the horizontal water permeability test showed the water permeability coefficient of each depth in the improved area was less than 1×10-5cm/sec.

In addition, according to the contract requirements, 2 continuous core drilling samples and 6 sets of unconfined compression tests were carried out. The test results were all above the specified standards.

After that, there was no water inrush or sand inrush during the process of TBM break-through at the launch face, and the geological improvement by high-pressure jet piles at the launch site of the TBM was successfully completed.

―

TBM Launch Site Geological Improvement By High Pressure Jet Piles

將下載檔案寄至:

・More Construction Result Sharing

Contact us:+886 2769-2355

Copyright ©Jines Construction Co.,Ltd