DIAPHRAGM WALL GUIDE TRENCH COLLAPSE GROUND IMPROVEMENT

Strata filling, reinforcement, water stopping composite grouting

―

1. Project Background

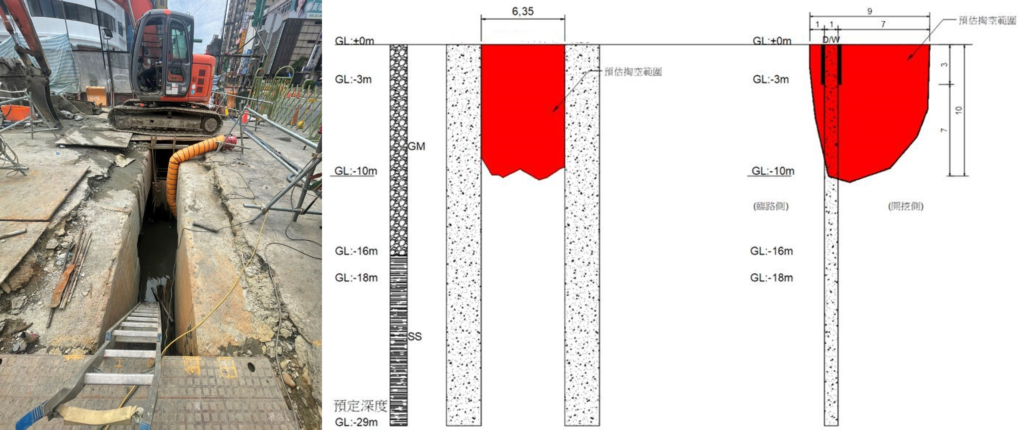

A collapse occurred during the excavation of a diaphragm wall guide trench at GL.-29m. Due to the presence of an underground culvert nearby, the construction unit immediately backfilled the guide trench to GL.-3m below the lower edge of the culvert to prevent further collapse and potential damage to the culvert.

Additionally, a professional contractor with experience in such situations was commissioned to develop a ground improvement plan for the area surrounding the collapse location and oversee its implementation.

―

2. Solution

The geological conditions within the excavation area of this site were as follows: backfill layer, gravel layer, and silty sandstone layer, with the groundwater level at approximately GL.-3m. Due to the presence of silty sand with higher permeability above the gravel layer, it was necessary to reinforce both the disturbed gravel layer and the backfill layer while mitigating the impact of groundwater on the excavation of the guide trench after resumption of work.

The proposed composite ground improvement scheme was as follows:

- Excavate and fill the area with ground improvement materials.

- Implement protective ground improvement measures around the guide trench.

- Validate the pressure using the split spacing method.

- In areas where pressure verification fell short of requirements, supplement with additional grouting.

―

3. Works Design

The collapsed area on-site measured approximately 9m in length and 6.4m in width, with an estimated initial collapse depth of about GL-10m, gradually extending to the surface thereafter. Since emergency backfilling utilized soil obtained on-site and compaction filling was not feasible, the extent and depth of ground disturbance required investigation through borehole drilling.

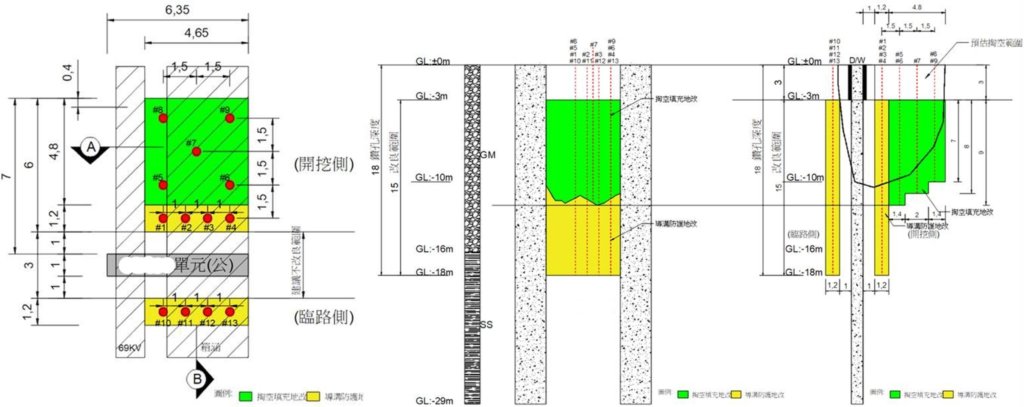

The relevant construction design included:

- Placement of 5 grouting holes within the collapsed backfill area, initially using drilling rigs to determine disturbance range based on drilling and debris removal conditions.

- Implementation of dual-pipe grouting method, combined with FLW cement chemical grout, for ground improvement filling within the disturbance range.

- Placement of 4 grouting holes on each side of the diaphragm wall, set back by 1m, for guide trench protection grouting. Grouting depth to extend 2m below the sandstone layer to ensure coverage of the gravel layer and backfill area.

- Utilization of dual-pipe grouting method for guide trench protection grouting, combined with instant-setting SSA chemical grout and slow-setting FLW cement chemical grout for infiltration and compression ground improvement.

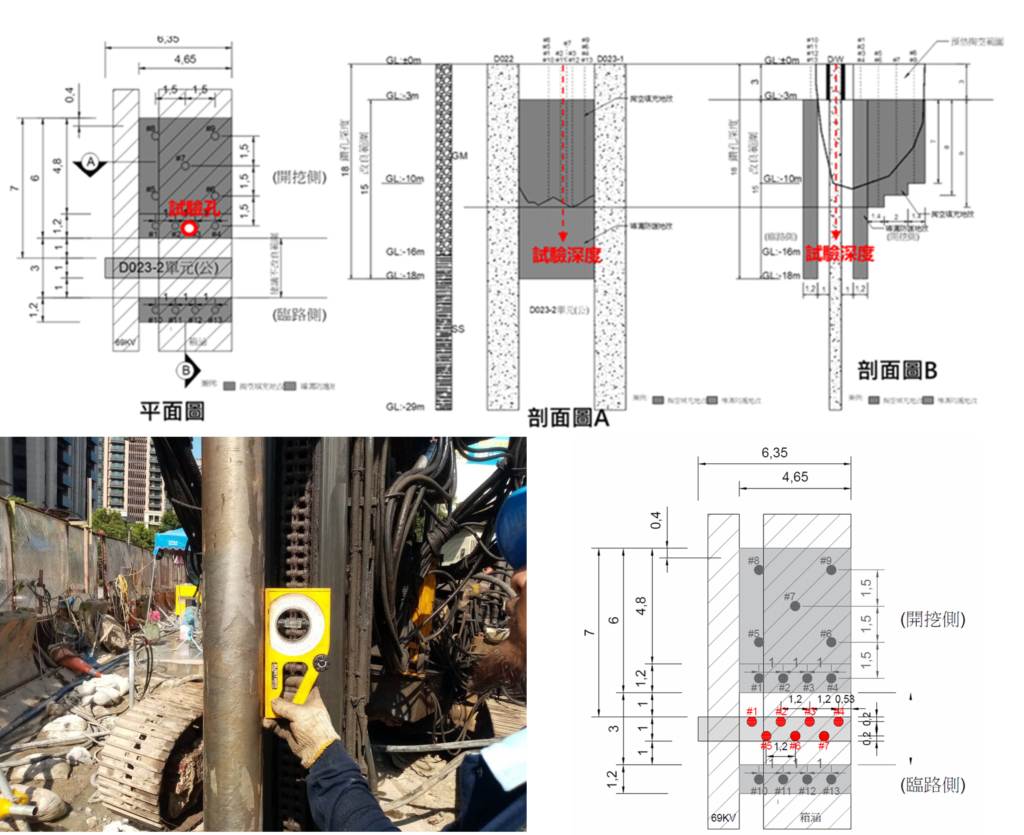

- Conducting pressure verification using the split spacing method at locations specified by the owner, with the verified hole reaction pressure exceeding the maximum pressure recorded at surrounding grouting holes.

- Supplementary grouting conducted at locations with insufficient pressure verification.

―

4. Works Process & Results

Because the collapsed area was mainly a gravel layer, the ground improvement process began with drilling rigs followed by the dual-pipe grouting method using hydraulic rotary drilling rigs, which proceeded smoothly.

To ensure the safety of the excavation of the diaphragm wall guide trench, the construction unit additionally conducted grouting with SSA chemical grout in 7 holes within the guide trench excavation area, targeting gravel and backfilled soil. This was done to mitigate the impact of groundwater pressure during the resumption of excavation in this section.

―

5. RESULTS

Following the construction design procedures for filling grouting, protective grouting, and additional guide trench water-stop grouting as per the owner’s request, the on-site pressure verification results were good. After resuming work, the excavation of the diaphragm wall guide trench proceeded smoothly.

There were no occurrences of sidewall collapse or intrusion during the process of inserting reinforcement cages and grouting with high-density pipe concrete. The ground improvement work for the collapsed area of the diaphragm wall guide trench was successfully completed.

―

・More Construction Result Sharing

Contact us:+886 2769-2355