SITE IMPROVEMENT FOR EXCAVATION OF UNDERGROUND PASSAGEWAY IN LATERITE GRAVEL LAYER

Double-packer horizontal grouting technology

―

1. Project Background

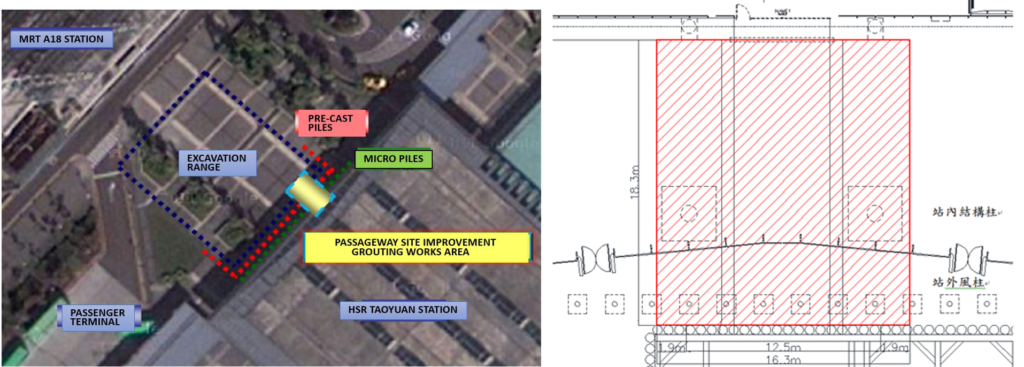

A new underground passage was planned to be constructed between an MRT station and an adjacent high-speed rail station to facilitate passenger transfers. The newly completed MRT tracks were elevated, while the operational high-speed rail ran through an underground tunnel. The connection between the two includes an open-cut underground space between the stations and a partially underground mined passage through the high-speed rail station.

To prevent any risk to the operation of the high-speed rail, protective measures such as pre-cast piles and micropiles had to be implemented around the high-speed rail station. Additionally, in areas where surface construction is not possible for the mined passage, ground improvement and reinforcement will be carried out using double-packer horizontal grouting technology.

―

2. Solution

Due to the geological conditions of the construction area, which consists of continuous laterite gravel layer, the primary goals were to enhance the cohesion of the gravel layer and reduce the permeability coefficient of the strata to prevent collapse and deformation during construction.

The related operational plan was as follows:

1. Coordinate excavation with staged drilling and grouting in the open-cut area.

2. Use the double-packer horizontal grouting method to minimize disturbance to the strata.

3. Apply CB grout as the filling material and use ultra-fine cement as the permeation reinforcement grout.

4. Accept the work based on the results of on-site permeability tests and the absence of water and sand seepage phenomena observed on the surface.

5. Use an automatic laser scanner to perform real-time monitoring of the high-speed rail station floor during each stage of the operation. In case of any abnormal deformation, immediately halt the construction and implement emergency response measures.

―

3. WORKS DESIGN

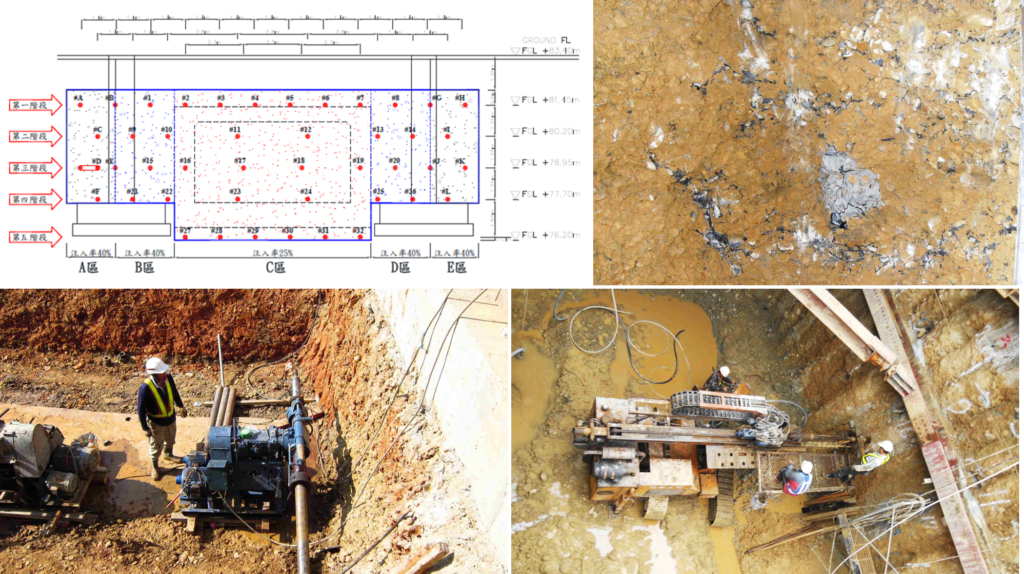

To coordinate with the open-cut area operations, the construction process was to adopt a staged approach involving drilling, pipe embedding, and grouting. The construction design included the following steps:

1. Based on stability analysis and avoiding the underground structures of the high-speed rail station, determine the improvement scope.

2. Divide the grouting area into five drilling stages according to elevation. Stages 1 to 4 have a vertical spacing of 1.25m, and stages 4 to 5 have a vertical spacing of 1.5m, with a horizontal spacing of 1.4m at the same elevation. The drilling positions are to be staggered across different stages.

3. Conduct horizontal drilling and pipe embedding according to the depth of the open-cut section. Use hydraulic rotary drilling machines for the upper part and percussion drilling machines for the lower part, employing OD118mm casing for drilling.

4. After the casing reaches the design depth, insert Marshall pipes with check valves every 33.3cm.

5. Remove the casing and seal the end of the drill hole, then use double-packer internal pipes to inject CB grout in stages for external sealing.

6. After curing the CB sealing material for 2-7 days, create a grouting path using clean water splitting, then fill the weak zones with CB grout and perform ultra-fine cement permeation grouting. Complete all grouting at the same stage before proceeding to the next stage.

7. Grouting pressure should be the initial injection pressure plus 5-20 kPa. If the grouting pressure cannot reach the predetermined level, increase the actual grout quantity or perform supplementary grouting.

8. After grouting, conduct a water test, with a permeability coefficient not exceeding 1×10^-5 cm/sec considered acceptable.

9. Once the water test is passed, break the surface layer. There should be no water or sand inrush at the excavation face.

―

4. Works Process

The construction and water testing process proceeded smoothly. After breaking the surface layer, only a small amount of seepage was observed in the corners. This was addressed with localized supplementary grouting, which gradually stopped the seepage. After a period of observation with no further seepage detected, the dismantling of the scaffolding and site cleanup operations commenced.

―

5. RESULTS

After breaking the surface layer, the excavation face demonstrated excellent stability, and the improvement of the gravel layer with ultra-fine cement was visibly evident. To save time, the original plan for sectional excavation was modified to full-section sequential excavation after evaluation by the relevant units.

Throughout the excavation process, real-time monitoring inside and outside the high-speed rail station showed no abnormal deformations exceeding the warning thresholds. The ground improvement work for the underground passage through the laterite gravel layer was successfully completed.

―

・More Construction Result Sharing

Contact us:+886 2769-2355