GROUTING TECHNOLOGY FOR NEW TUNNEL INVERT SERIOUS SEEPAGE

The most rapid and effective method for invert slab leakage stoppage and reinforcement.

1. Project Background

A subsurface excavated subway tunnel in Southern China suffered serious water seepage after the invert slab and track laying had been completed.After the construction crew carried out injection of modified epoxy resin, the water leakage became more serious, causing serious water accumulation in the drainage ditch.

In order to completely solve the water leakage problem, the main contractor specially commissioned Jines to conduct on-site investigation and invert slab leakage water remediation.

―

2. Solution

After the company assigned professional engineers to conduct on-site surveys and inspect the tunnel lining construction photos, it was found that there were unidentified waste materials in the concrete during the lining construction.

This may have caused leakage of the pipelines and subsequent cracking of weakened concrete surfaces. Incorrect drilling and grouting methods when the construction team injected the leak-stop materials on their own, were also reasons for the aggravated leakage.

Fortunately, there was no mud and sand overflow from the existing cracks. When formulating the solution, the main goals were to install waterproof membrane in the space behind the lining, fill in the voids, and add strength.

―

3. Works Design

Because the track inspection vehicle and construction material carrier had already started operation during the company’s work, some of the defective invert slab had undergone serious cracking and needed to be re-poured after being subjected to dynamic loads.

For the works design, the flexible and rigid resin composite construction method successfully used in Europe, America and Japan and high-quality grout made in Taiwan were employed.

First, micro-expanding elastic PU grout was used to form a waterproof membrane between the first and second linings, and then rigid non-expanding PU mortar with a compressive strength of more than 40MPa was used to fill the voids and to bond cracks between the linings.

The curing time of PU grout was set to within 1 hour, so that the grout had reached the expected strength when the construction vehicles pass. In order to not affect the strength of the invert slab and at the same time to make the injected grout reach the designed injection position, oblique micro-drilling was used, and the drilling location was mainly positioned in the drainage ditch and maintenance channel.

―

4. Works Process

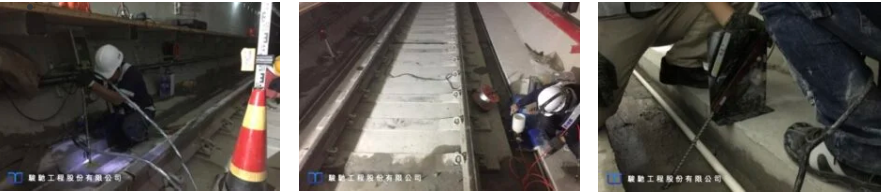

Although the subway tunnel was still not open to traffic, various work shifts and owner inspection work were frequently carried out, and the work was mainly based on small machines.

Grouting boreholes, and in addition directional drilling with a special angle fixed plate, and drilling in stages to bury a miniature waterstop valve to avoid mud and sand inrush caused by one-time penetration.

During grouting, it was synchronized with an alarmed laser level of accuracy greater than 0.5mm for real-time monitoring to accurately control the injection pressure and the amount of grout injected.

―

5. Results

After injecting micro-expanding elastic PU grout to form a waterproof membrane, the invert slab leakage was greatly reduced.After filling the voids and concrete cracks with rigid non-expanding PU grout, all invert slab leakage stopped, and the small amount of moisture on the drainage ditch side walls would not affect the normal operation of the future subway.

After the inspection and confirmation by the main contractor, the serious water seepage treatment of the tunnel invert was successfully completed.

―

Treatment Technology For New Tunnel Inverted Arch Serious Seepage.

將下載檔案寄至:

・More Construction Result Sharing

Contact us:+886 2769-2355

Copyright ©Jines Construction Co.,Ltd