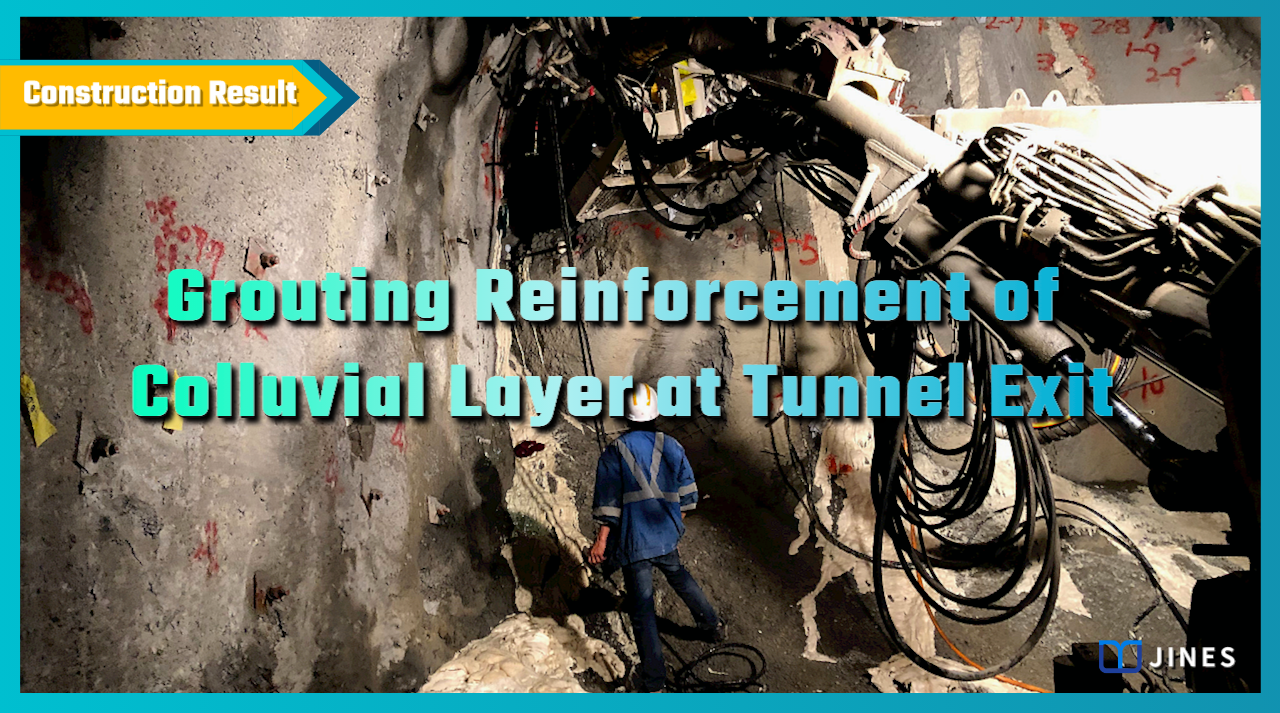

Grouting Reinforcement of Colluvial Layer at Tunnel Exit

GROUTING REINFORCEMENT OF COLLUVIAL LAYER AT TUNNEL EXIT Case study of self-drilling hollow rock bolt grouting reinforcement ― 1. Project Background Above a newly constructed highway tunnel, an exhaust/smoke vent tunnel was installed within a cavity. Due to the steep terrain at the tunnel exit location, external level excavation was not feasible. When the flue

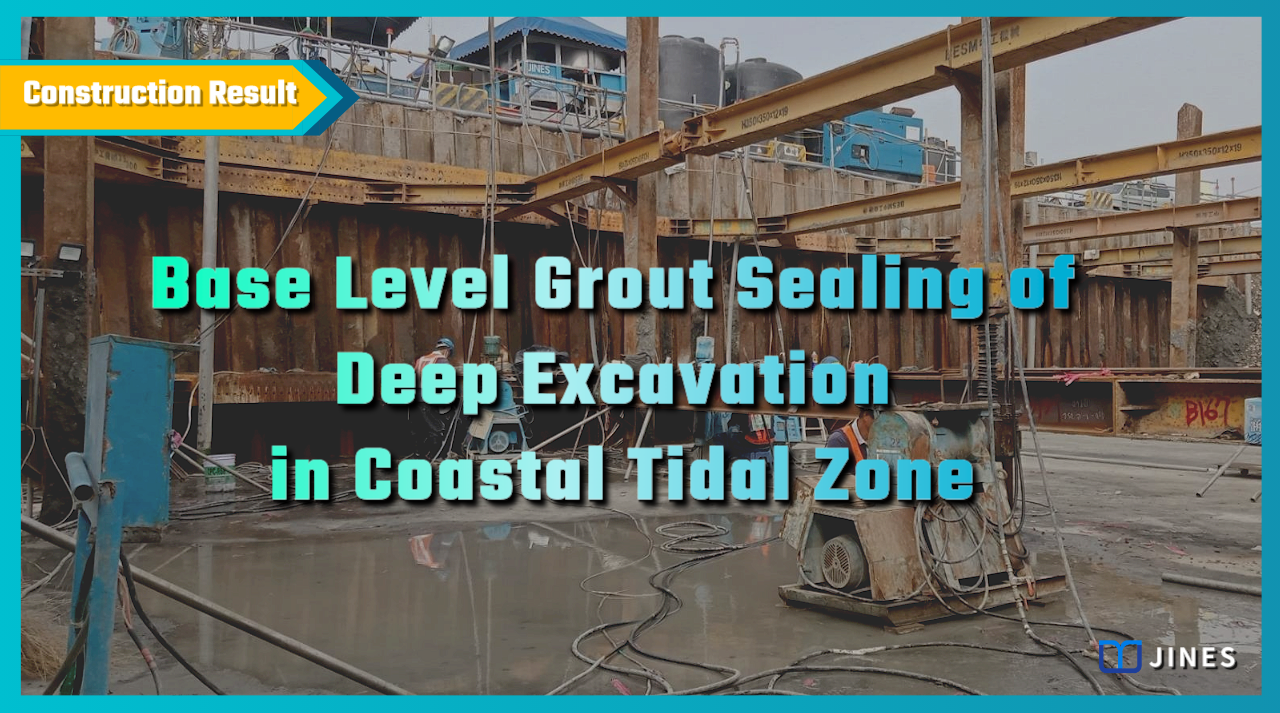

Base Level Grout Sealing of Deep Excavation in Coastal Tidal Zone

BASE LEVEL GROUT SEALING OF DEEP EXCAVATION IN COASTAL TIDAL ZONE Water-stop grouting site improvement technology for base level excavation in saline-alkali area — 1. Project Background A proposed ecological landscape-based seawater supply system was planned to be constructed in a coastal tidal zone. It involved the construction of work shafts and diversion channels. However,

Site Improvement of Technical Backfill Area Adjacent to Bridge Abutments

SITE IMPROVEMENT OF TECHNICAL BACKFILL AREA ADJACENT TO BRIDGE ABUTMENTS Double-packer grouting for homogenization of porous granular backfill and load-bearing capacity enhancement — 1. Project Background In order to ensure long-term operational safety of a light rail bridge abutment, the technical backfill area at the approach section was to be filled with graded gravel. However,

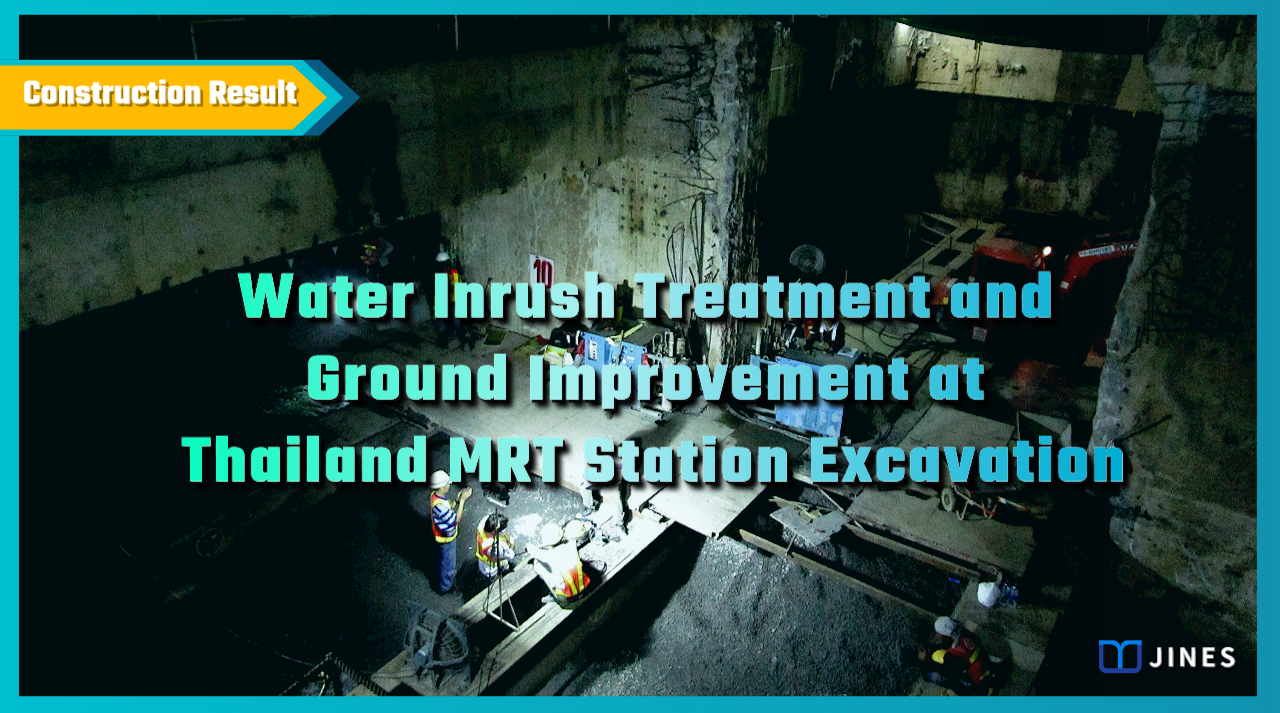

Water Inrush Treatment and Ground Improvement at Thailand MRT Station Excavation

WATER INRUSH TREATMENT AND GROUND IMPROVEMENT AT THAILAND MRT STATION EXCAVATION Water-stop and stabilization improvement of site damaged by ground uplifting 1. Project Background In a Thai MRT station construction project, the reverse construction method was employed, with diaphragm walls penetrating into the clay layer below the excavation level to prevent groundwater infiltration. However, an

Abnormal Machine Vibration: Reinforcement of Industrial Factory Foundation

ABNORMAL MACHINE VIBRATION: REINFORCEMENT OF INDUSTRIAL FACTORY FOUNDATION Ground improvement by loose zone fill and weak zone compaction grouting in soft soil site 1. Background An industrial plant experienced abnormal vibrations in some of its machines after a period of operation. In order to prevent disasters, the management decided to commission a professional firm to

Ground Improvement at Launching Site of TBM Tunnel in Composite Strata

Ground Improvement at Launching Site of TBM Tunnel in Composite Strata Integrated Ground Improvement using Full-Length Casing Piles, High-Pressure Jet Grouting, and Double-Packer Grout Injection 1. Project Background The launching site of an underground TBM tunnel was located at a depth of GL-35.1m to GL-40.2m below the ground surface. The upper part of the tunnel

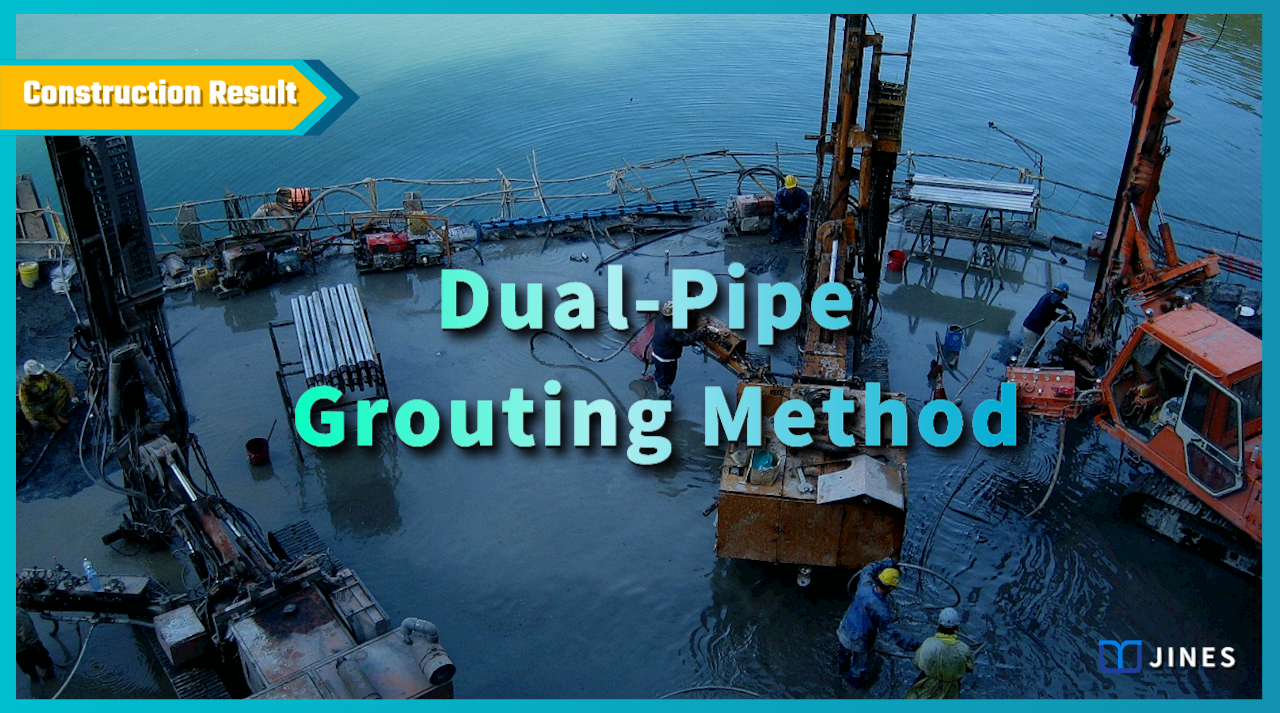

Dual Pipe Grouting

1. Dual Pipe Grouting The dual pipe grouting method is a versatile low-pressure grouting technology suitable for various formations and grout materials, with adjustable grout curing time. In this method, the strata are treated through 50cm sequential or reverse grouting intervals, allowing for effective treatment of compacted, split, vein intrusion, or plugging. The unique characteristic

Chemical Grout Materials

1. Chemical Grout Materials Chemical grout materials are used in injection into the ground strata to increase strata strength, reduce permeability, and prevent liquefaction. They achieve these purposes through processes such as penetration, diffusion, gelation, or solidification. Commonly used chemical grout materials include true solutions (ionic solutions) and gel-like suspensions (colloidal solutions), which generate gelation

Repair of Leakage in Sewer RCP Pipe Joints

REPAIR OF LEAKAGE IN SEWER RCP PIPE JOINTS Pipe leak sealing and surrounding ground improvement and reinforcement techniques 1. Project Background A sewage RCP pipe in a sewer system was suspected to have developed cracks in the joints due to nearby construction activities, resulting in inrush groundwater containing fine sand into the pipe. To prevent

In Use Underground Station Side Walls and Shallow Buried Tunnel Water Seepage Sealing

IN USE UNDERGROUND STATION SIDE WALLS AND SHALLOW BURIED TUNNEL WATER SEEPAGE SEALING Ground improvement and repair technology for water & sand leakage in diaphragm walls expansion joints, and structural cracks. 1. Project Background An underground MRT station and shallow-buried tunnel sidewall experienced water leakage and localized soil infiltration after operating for a period of