EMERGENCY GROUT PLUGGING OF SOIL RETAINING PILES, WATER AND SAND INRUSH

Instant & retarded composite water-stop grouting technology

1. Project Background

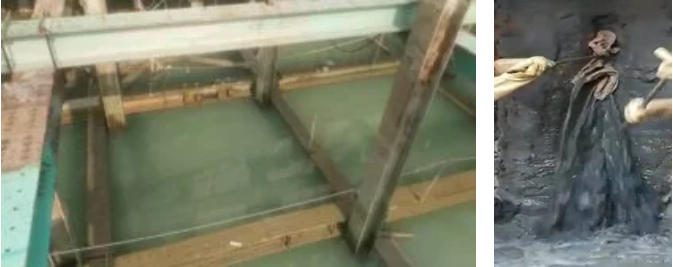

When the basement of a project was excavated to about GL-7.0m, water and sand inrush suddenly appeared on the excavation surface and at the gaps between some retaining piles.The construction crew tried manual packing and horizontal resin grouting, but the site conditions did not improve significantly.

To prevent the ongoing inrush of sand and soil from causing damage to adjacent buildings, roads and pipelines, the constructors carried out emergency water injection into the foundation pit to slow down the water inrush.

In addition, professional contractors with relevant experience were entrusted to propose solutions and deliver them for implementation.

―

2. Solution

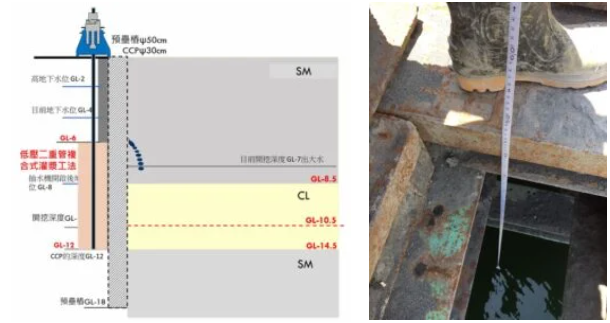

The groundwater level of the base was about GL-2.0m, the surface to GL-8.5m was a silty fine sand layer. GL-8.5m~GL-14.5m was a silty clay layer with thin layer of fine sand. GL-14.5m~GL-20.0 m again turned into a silty fine sand layer.

The basement excavation depth was GL-10.5m, and densely-packed prepacked-piles of diameter 50cm and length 18m had been used, together with CCP water-stop piles with a diameter of 30cm and a length of 12m, as soil retaining facilities.

Because the CCP water-stop pile had penetrated deep into the clay layer, and the lateral water inflow points are mostly around GL-6.0m, the reason for the water inflow should be determined because the CCP water-stop pile has a poor forming effect in sand layers.

As a result, the water-stopping effect was not as they had expected. In order to relieve the water and sand inrush as soon as possible and ensure the safety of surrounding structures, it was planned to use the double-pipe grouting method behind the retaining piles, and use instant and retarding grouting materials for composite grouting water inrush plugging and stratum filling.

At the same time, with skip-hole convergence technology, the ground layer is to be squeezed to achieve the effect of formation reinforcement.

―

3. Works Design

Although the water leakage points at the sides of the retaining piles and the excavation surface could be directly observed visually, the permeable paths and hollowed positions in the stratum were mostly irregular.

In order to effectively seal the permeable path, fill the hollow block and improve the weak zone of the stratum, the superimposed composite grouting technology is specially used to seal the water.

The relevant plans are as follows:

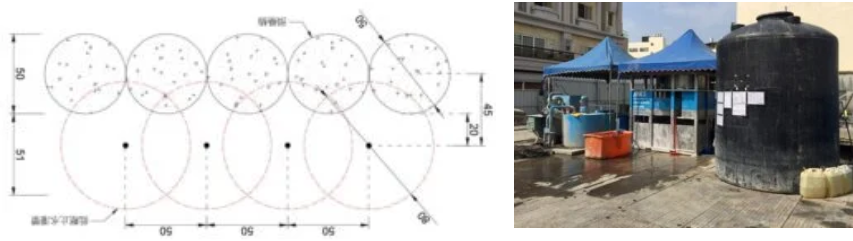

(1) At 20cm back of the retaining piles, set parallel site improvement grouting holes with a spacing of 50cm.

(2) The improvement depth is GL-6.0m~GL-12.0m, which completely covers the current water leakage point, the sand layer below the water leakage point and the silty fine sand interlayer in the clay layer below.

(3) The improvement hole was of diameter 80cm, and the overlapping range of the grout was 30cm, which fully covers the original CCP waterstop piles and overlaps the retaining piles by 20cm. Effectively plug all seepage paths in the geological improvement range, fill holes, and perform light to moderate squeeze grouting on the stratum.

(4) Odd-numbered holes are used as main grout holes, and even-numbered holes are convergent holes for skip-hole grouting.

(5) With 50cm as the step depth, each hole is firstly grouted in a step-by-step manner to seal the water inrush by instant-setting SSA chemical grout. Use FLW retarded cement-based chemical grout to fill the holes, and then reverse grouting in the same hole with the same pouring procedure for primary convergence.

(6) The outlet pressure of the main grouting hole is controlled below the groundwater pressure at this depth + the passive earth pressure of the unimproved stratum. The outlet pressure of the convergent hole is controlled below the groundwater pressure at this depth + the passive earth pressure of the improved stratum.

(7) Adjust the outlet pressure and flow rate of the grout appropriately according to the monitoring value of the grouting pressure change, the deformation of the retaining facility and the support strain.

―

4. Works Process

The construction process went smoothly.As the last few convergent holes were grouted, the grouting feedback pressure was high and localized retaining support strain had a nonlinear upward trend because the formation voids and weak zones in the improvement range had been fully filled and moderately squeezed.

After moderately reducing the grouting pressure, all the geological improvement work was successfully completed within the safety monitoring and control values.

―

5. Result

After the grouting work was completed and the water in the excavation area was drained, it was found that the water inrush phenomenon in the original foundation had been completely eliminated.

After the downward trial excavation, there was only a small amount of water seepage in a few places, which did not affect the excavation of the basement, the subsequent PC layer pouring and the binding of the foundation rebars.

This successfully completed the emergency grouting and plugging of soil retaining piles, water and sand inrush.

―

Emergemcy Grout Plugging of Soil Retaining Piles, Water and Sand Inrush

將下載檔案寄至:

・More Construction Result Sharing

Contact us:+886 2769-2355

Copyright ©Jines Construction Co.,Ltd