DEEP FOUNDATION EXCAVATION WATER INRUSH LOW-PRESSURE GROUTING SEALING

Dual-Pipe Grouting Method Inrush Water sealing technology

1. Project Background

The foundation excavation depth of a civil building was GL-23.25m, and the top-down excavation method was being used for the works. When the building was being excavated close to the bottom of the foundation, four water inrushes occurred near the dewatering well and around the buttresses.

The water inrush was about 20.9 cubic meters per hour. Because fine sand was carried in the influx, in order to prevent the formation from hollowing out and protect the completed basement equipment in the upper part, the construction unit urgently adopted water injection and increased water lowering to maintain the dynamic water pressure balance.

They invited professional contractors to discuss countermeasures for water influx plugging.

―

2. Solution

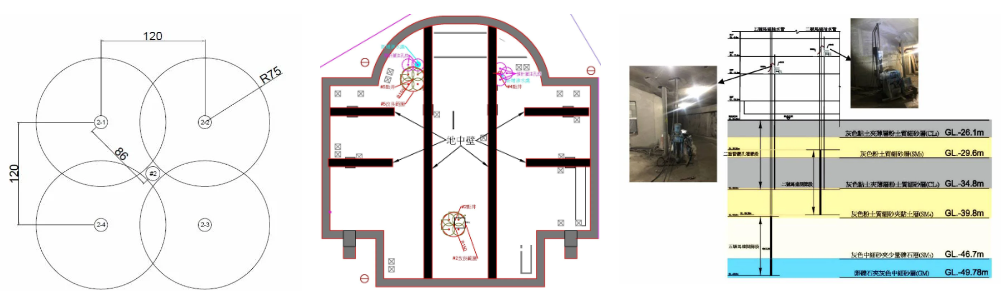

The foundation was located in a select metropolitan area. The geological conditions were sedimentary strata. Above the GL-39.6m surface were interlayers of clay, silt and medium-fine sand, and below the surface were pebble gravels containing confined water sandwiched with medium-fine sand, and the groundwater level was about GL-3.0m.

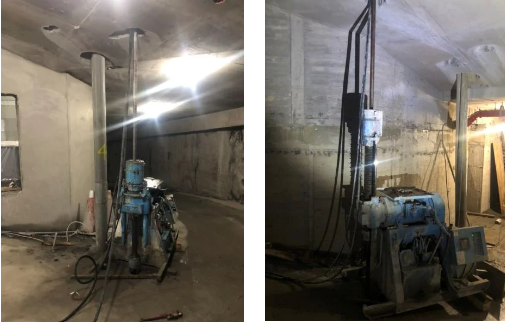

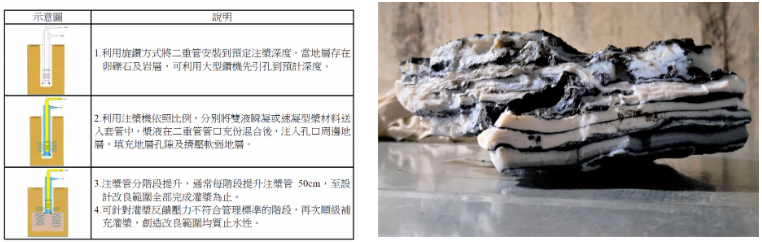

According to the site conditions and the comprehensive evaluation of the applicability of various water inrush plugging methods, it was decided to use the instant and retarded SSA chemical grout and FLW cement chemical grout, and the Dual Pipe Grouting Method using small drilling rigs.

Small-scale filling, extrusion and permeation grouting to be carried out around the leakage point to form multiple underground plugs to achieve the effect of water inrush plugging and formation reinforcement.

―

3. Works Design

In order to form the stratum sealing effect in the water inrush range, the sedimentary stratum between GL-23.25m and GL-35.00m of the foundation to be used as the grouting improvement range.

GL-26.10~GL-29.6 gray silt fine sand layer under the excavation surface to be the first main plugging area, to be fully filled and permeated with instant and retarded grout materials to reduce the water permeability of the stratum.GL-29.6~GL-34.8 above was gray clay sandwiched on thin silt fine sand layer.

Below was the second main plugging area, to be extruded and poured with instant and gelling grout materials to form a plugging effect in the strata and block the permeation path of the confined water below.

The grouting hole spacing is 120cm, the penetration distance is 75cm, and the grout overlap range is 30cm. The ring configuration is mainly used. When encountering underground structures, the secant configuration is used to pull back by 30cm depending on the situation.

The grouting pressure is set according to the passive earth pressure and grouting depth that do not cause soil splitting disturbance, and the initial grouting pressure is between 370kPa and 630kPa.

To meet the overlapping requirements of the grout and the strength of the grout after curing, the final grouting pressure should be no more than 570kPa~830kPa.

―

4. Work Process

Due to the urgency of this project, and the dynamic balance method of water injection adopted on site, the water and sand inflow were reduced.

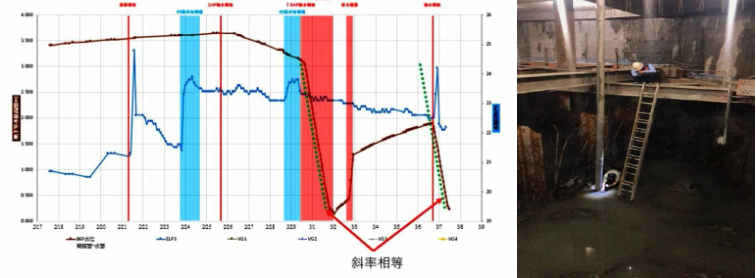

After completing the grouting according to the optimized design, it was impossible to judge the grouting results by means of the on-site water permeability test and visual judgment.

When verifying the effect, measures were adjusted according to localized conditions and use of on-site controllable conditions:

(1) Observed for any pumped water returning, confirmed that there was no obvious return phenomenon of water level after water reduction.

(2) Comparison of the slopes of the multi-cycle water reduction graphs over time, the consistency of the slopes of the graphs of the water level height during water injection and pumping verified that there was no obvious water inrush in the basement.

(3) Compared the monitoring value of the water pressure gauge under the excavation surface with the water reduction time graph of the basement to confirm that the water pressure of the highly permeable layer was not affected by the water reduction, and the grout sealing effect was verified.

(4) Water lowering reached the bottom of the excavation; observed the water flow condition, and visually verified the sealing effect.

―

5. Results

After sealing, filling, permeating and reinforcing the stratum at the location of the water inrush using the dual pipe grouting method, various tests and verifications showed that the permeable pathway of the stratum and the weak zone of water inrush disturbance had been effectively sealed.

When the pit was pumped to the foundation elevation, a comprehensive inspection was carried out to confirm that there is only a small amount of water seepage on the excavation surface.

A temporary sump combined with a wastewater pump could be used for smooth removal without affecting the excavation and subsequent construction. The deep foundation excavation water inrush and low-pressure grouting work had been successfully completed.

―

Deep Foundation Excavation Water Inrush Low-Pressure Grout Sealing

將下載檔案寄至:

・More Construction Result Sharing

Contact us:+886 2769-2355

Copyright ©Jines Construction Co.,Ltd