PROTECTIVE GROUTING FOR TUNNEL EXCAVATION IN FRACTURED ROCK FORMATION

Pre-construction pipe-roof support grouting reinforcement

1. Project Background

A tunnel was being excavated by drilling, blasting and mechanical excavation. A section of the tunnel passed through fractured rock formations with underground water veins about 62m long.

To prevent collapse, water inrush, rockslide and excessive over-excavation during construction, the construction unit planned to use water-stop reinforcement grouting and the support pipe-roof construction method for protection in this section.

Contractors with similar construction experience were invited to cooperate in detailed planning and implementation.

―

2. Solution

To achieve smooth excavation of the fractured rock section, the following solution was formulated:

(1) Use low-pressure grouting for water-stopping and consolidation grouting in fractured rock formations;

(2) If a large amount of water inrush is encountered during the grouting process, a drainage hole with a depth of more than 50m~60m should be first made to reduce the amount of water inflow and water pressure in the improvement area;

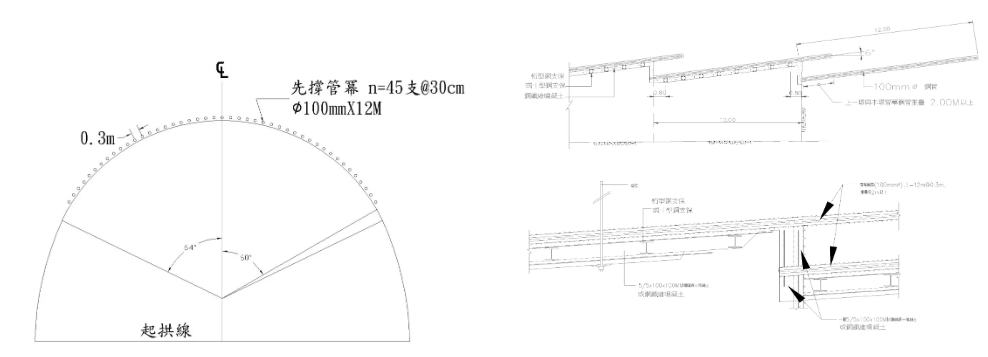

(3) Using steel pipes and grouting technology to set up pipe-roof along the outer edge of the tunnel excavation line, as the pre-support to protect the arch supports on the advancing excavation face.

(4) Use the method of alternating advance “support first and then excavate” in sections.

―

3. Works Design

According to the conditions listed in the solution, the works design was as follows:

(1) Define the fracture conditions of the rock formation and the groundwater content according to the data of the advancing detection holes;

(2) According to its characteristics, FLW cement chemical grout or polyurethane resin was to be used for the sealing of rock cracks in highly permeable rock formations.

(3) Intrusive grouting to be carried out with W/C=0.6~1.0 cement grout in the fractured rock formation depending on its grout absorbing condition. This will consolidate the fracture zone and improve the bonding capacity of the joint surfaces;

(4) Use the Top Hammer system for construction, and choose the pre-support pipe roof method or the non-expansion excavation method according to the characteristics of the rock formation;

(5) Packer grouting method to be used; grouting holes arranged within 45 degrees of the upper half of each ring, which can be adjusted according to the site. The drilling elevation angle about 5~10 degrees;

(6) Length to be grouted was 9m from the bottom of the pipe, and the grouting hole is filled from the bottom of both sides to the top;

(7) Initial value of grouting pressure is to be 200kPa, and the pressure should be kept between 300 and 1800kPa according to the design flow. Maximum should not exceed 2000kPa;

(8) Length of excavation was about 62m; grouting was divided into 7 sections. Grouting depth is 12m each time.

―

4. Works Process

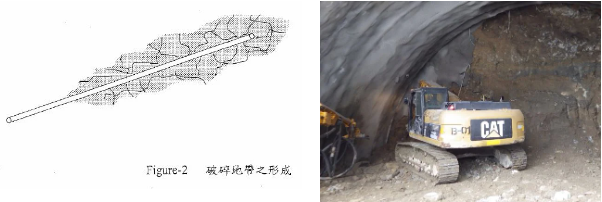

Rock grouting often has great variability due to the different degree of rock fragmentation and development of joint surfaces.

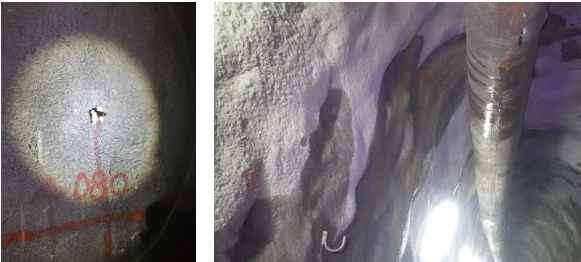

This project adopted the packer grouting method. The grouting openings were 30cm apart, and the grouting was staggered, with an effective range of 1.0m. The initial cement grout W/C was 1.0.

If the amount of grout was large, the pressure could not be increased and the exhaust pipe was not continuously producing back grouting, then the cement grout W/C was adjusted to 0.6 and continued with intermittent grouting.

When the grouting pressure rose steadily and the grouting volume was close to the design value, the grouting pressure not less than 1500kPa and grouting consumption was less than 5 liters in 3 minutes, this was considered as the grouting completion for that hole.

―

5. Results

The process of consolidation grouting, pipe-roof grouting and alternating advance excavation was generally smooth. Where the localized rock formation was relatively broken and there was water inrush, self-drilling hollow rock bolts and water-stop grouting could be used to stabilize rock and block water inrush.

After excavation of the fractured rock stratum section was completed, there were only a few places left on the excavation face where there was still water seepage. After supplementary anti-leak grouting, the pre-brace support grouting work was completed for the tunnel excavation through the fractured rock strata.

―

・More Construction Result Sharing

Contact us:+886 2769-2355

Copyright ©Jines Construction Co.,Ltd