HOT BITUMEN REINFORCEMENT METHOD FOR TUNNEL CAVE-IN WATER INRUSH

The fastest and most effective reinforcement technology to prevent large-scale tunnel cave-in water inrush.

1. Project Background

Hot Bitumen Reinforcement Method : When a mountain tunnel was being excavated, a rock fracture zone was encountered, with a collapse of the excavation face. The water outflow was as high as 50 ~ 80m3/min, and the maximum water inrush pressure of the excavation face was as high as 4,000kPa.

―

2. Solution

After coordination by all units, it was decided to abandon a part of the caved-in tunnel, excavate two alternative tunnels, and construct a sealing wall in front of the fracture zone to carry out long-hole drilling for hot bitumen grouting to stabilize the broken rock layer and block the groundwater inrush path.

―

3. Works Design

Due to the large scale of the fractured zone and the uncertainty of its extent, after performing horizontal drilling to define the extent of the fractured zone, a long, drilled drainage pipe was set up at the works area to reduce part of the water pressure and observe the application of the hot bitumen grout.

During grout injection, the drilling depth was about 70m. A specially-made sleeve valve pipe that horizontally penetrated the fractured zone about 18 ~ 24m and a special dual-pipe for preheating were used to connect the grouting line. The hot bitumen is not easily washed away by water. Meeting cold (groundwater) the surface condenses into a hard shell.

Then when heated (subsequent injection of hot bitumen), it has the characteristic of re-melting, so it advances forward into the rock fracture zone, filling the cracks and strengthening water-stopping.

―

4. Works Process

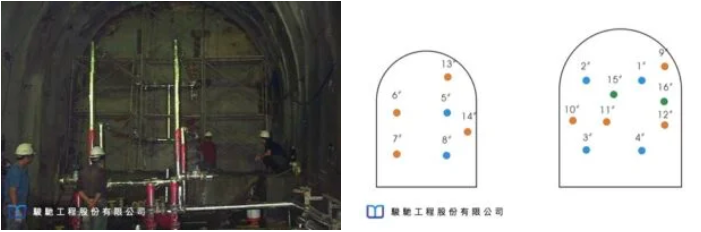

The company carried out a total of 16 boreholes of hot bitumen grouting in two tunnel fracture zones.This was divided into three stages. In order to avoid polluting the mountain spring water, No. III hot bitumen with environmental protection characteristics was selected as the grouting material, and natural palm oil was used for preheating.

The temperature of the hot bitumen outlet was controlled at about 160 ~ 200oC. The injection pressure was 7,000 ~ 12,000kPa, and the total pouring volume was about 3,100m3.

―

5. Results

After grout injection into 6 boreholes in the first stage, the amount of water in the embedded water pipe had decreased.After completion of grout injection into 8 boreholes in the second stage, return grout appeared in the outlet pipe and the water volume had greatly reduced.

During the third stage of grout injection, the drainage pipe was intermittently closed and the pressure was partially raised to allow hot bitumen to fully fill the micro-detailed surface of the rock layer, and the water flow completely stopped.

After the hot bitumen was sufficiently cooled, on continuing excavation, the construction unit found that the fractured zone after the grout injection had structural integrity, and joint surfaces of the rock layer of less than 1mm were completely filled with bitumen.No water inrush occurred during the excavation process, and the excavation of the mountain tunnel through the fractured zones were successfully completed.

―

Hot Bitumen Reinforcement Method For Tunnel Cave-in Water Inrush

將下載檔案寄至:

・More Construction Result Sharing

Contact us:+886 2769-2355

Copyright ©Jines Construction Co.,Ltd