GROUTING TECH FOR CONSTRUCTION SITE EXCAVATION WATER INRUSH

Hot bitumen leak-stop tech use for water inrush at top-down method pit excavation

1. Project Background

The Top-Down construction method has many advantages, such as shortening the construction period and having little impact on adjacent buildings. It is often used in urban construction projects.

However, while employing the Top-Down process, if there are water wells, drilling holes or detector tubes buried in the base etc and these are badly plugged at the early stage, a large amount of water inrush at the excavation face is often caused by the wells & pipes connecting to the pressured water layer below.This causes construction to halt and even causes damage to nearby buildings and roads.

In this case, the Top-Down method was used to design, excavate 4 levels underground.The foundation level was on a silty clay layer, and there was still a clay layer with a thickness of more than 10m below it, and then it is connected to the high permeability silt layer.Where the retaining wall is designed with continuous walls, there should be no large amount of groundwater seepage during the excavation of the basement.

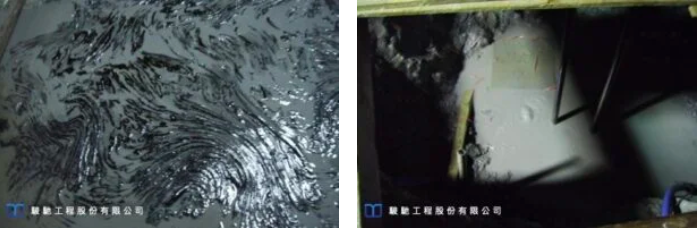

However, when the base was being excavated at about GL-14m, a sudden localized water and sand inrush occurred.The tremendous water pressure quickly washed out a hollow area full of mud around the water outflow point. The situation was very critical.

―

2. Solution

Since the contractor had had experience using hot bitumen technology to block water inrush when doing excavations, Jines Construction was notified to do a survey immediately after the accident, and promptly submitted a quotation and materials preparation was commenced.

After receiving the assignment, Jines immediately carried out works planning and various dispatching work, and quickly delivered the people, machines and materials to the site for operation within the time required by the owner.

―

3. Works Design

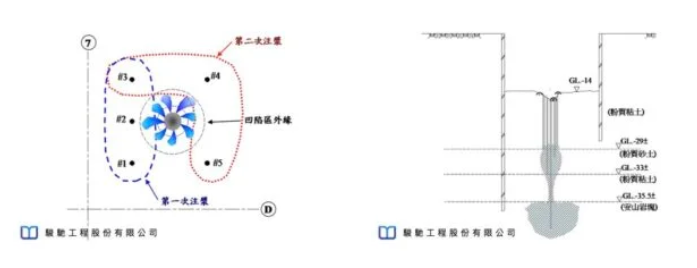

Because of the uncertainty of the scale and exact location of the inrush channel, the emergency rescue work was designed to be carried out as 5-hole hot bitumen grouting in two stages and 3 depths.

In the first stage, 2 holes were injected with grout at the outer edge of the inrush scoured-out area. The filling depth was at the interface between the clay layer and the silt layer.Hot bitumen was used to block the inrush channel, and the clay layer was compressed to narrow the waterway diameter.

In the second stage, on the opposite side of the water outflow point, it is divided into 3 depths and 3 holes of hot bitumen grouting, respectively plugging the interface between the clay layer below and the bottom sealing rock layer, and the sandstone layer with pressure.

The last hole is back to the interface between the clay layer and the silt layer under the foundation for final plugging.

―

4. Works Process

Because the Top-Down construction method was being employed on this project, Jines used special small hot bitumen pouring equipment suspended on the finished basement floor.

Hot bitumen with an outlet temperature of about 200oC was injected first, but the groundwater pressure too high, and some bitumen was brought to the inlet by the groundwater before solidifying.

After the experienced on-site engineers adjusting the hot bitumen temperature in real time, the water inrush passage was successfully plugged, and the water outflow quickly decreased.When the 5th hole in the second stage was injected according to plan, the water inrush completely stopped.

―

5. Results

Pit excavation was continued after the completion of hot bitumen grout plugging. During the process, only sporadic water seepage occurred in the base, which did not have any impact in the project’s progress.

The building construction project was successfully completed according to the scheduled period, and the adjacent houses and roads were not affected at all.

―

6. Recommendation

The actual grout injection time of this emergency work took only 4 days to completely eliminate the water inrush hazard, and the rest of the time was mainly for discussion meetings, personnel scheduling and machine assembly work.

It is recommended that when the Top-Down Method is used for construction or retaining projects that may have defects, excavation water inrush contingency plans can be prepared in advance, or an emergency mobilization contract should be signed with a contractor with extensive experience in hot bitumen grout injection rescue.

During the excavation of the basement, people, machines, and materials are ready standing by at any time to ensure that in case of emergency flooding, engineering accidents and delays in construction will not be caused.

―

Hot Bitumen Leak-Stop Tech Use For Water Inrush At Top-Down Method Pit Excavation

將下載檔案寄至:

・More Construction Result Sharing

Contact us:+886 2769-2355

Copyright ©Jines Construction Co.,Ltd