POLYURETHANE CRACK SEALANT GROUT MATERIAL CLASSIFICATION AND INJECTION METHODS

Long-Term Leak Stop, Reinforcement, Crack Injection Technology And Grout Material Selection.

1. Composition & Application

Polyurethane (PU), generally refers to a high molecular polymer containing urethane characteristics in the main chain of the molecule. Depending on the main agent and additives, it can take a variety of forms and uses.

It is used in daily necessities such as adhesives, coatings, gaskets, foams, plastic sponges, etc. For engineering applications, it is often used as paving, waterproofing and leak-proofing, crack injection reinforcement.

―

2. Grout Material Classification

Polyurethane grouting materials are often divided into the following categories because of their different purposes:

a) Water-activated swelling grout :

This type of PU pulp is mainly used for temporary structural leakage stop, using water as a catalyst.

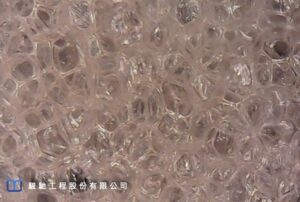

When the mixture is injected into the cracks of the structure and contacts the leaking water, the grout begins to generate densely packed bubbles to fill the gaps and block the water flow.

High-quality hydrophilic swelling grout (such as IP-125 series) can reach more than 90% response within 1 minute from encountering water, and the volume expansion ratio can reach more than 15 times.

b) Self-swelling grout:

Self-swelling PU grout does not require a catalyst. After curing, it has corresponding compressive strength according to different proportions. It is mainly used for filling and strengthening fractured rock layers, soil layers or concrete cracks (empty) gaps, water stop, and road or building jacking, etc.

When the mixed material is injected into cracks, densely packed bubbles are generated, and the gap is bonded and filled to achieve water stopping, filling and strengthening.

High-quality self-swelling PU grout (such as TIPOR-2 ~ TIPOR-15 series) can reach more than 90% response within 1 ~ 2 minutes after mixing, and the volume expansion ratio can be adjusted according to what is needed, 2 ~ 30 times.

c) Non-swelling elastic grout

Non-swelling elastic PU grout does not require a catalyst. After curing, it has elasticity and compressive strength.

It is mainly used for long-term repairs and leakage stop in earthquake zones and buildings (structure) with vibration characteristics.

It also is effective on the bonding broken (empty) cracks, soil layers or concrete cracks, filling and reinforcement, and water stopping.

Because of the long curing time of this type of slurry, when the mixture is injected into the crack by pressure pump, the grout can fully penetrate into the gap along the crack.

For high-quality non-swelling elastic PU grout (such as IP-108 series) curing time is about 30 ~ 50 minutes, with 1.0 ~ 1.1 times micro-expansion characteristics.

d) Non-swelling rigid grout

Does not require a catalyst. After curing, a rigid, cured mass with a uniaxial compressive strength greater than 30 MPa is formed. Because of its high compression, shear and flexural strength, it is suitable for the repair of large structures and the permanent repair, jacking and reinforcement of roads, tunnels and airport runways.

It is also effective for filling, strengthening and water-stopping cracked (empty) gaps in fractured rock, soil or concrete.This type of grout has a short curing time.

When the mixture is injected into the crack by the pump, the grout enters and adheres to the structure along the crack and cures quickly. Very low impact and high operational flexibility.

High-quality non-swelling PU grout (such as TIPOR-01 series) can reach more than 90% reaction within about 2 minutes after mixing, and has a micro-expansion characteristic of about 1.0 to 1.05 times.

e) Silicate resin grout

Silicate resin grout does not require a catalyst, and the material properties are similar to non-swelling rigid PU grout. It has higher coaxial compressive strength, but its adhesion, shear and flexural strength are slightly worse. There may be a small amount of bleeding and a small amount of shrinkage during use.

However, because the price of the raw material is lower than that of non-swelling rigid PU grout, it is suitable for engineering projects that target crack (void) gaps filling and have low requirements for adhesion and water resistance.

Because the market price of silicate resin grouts is very different, and the infusion effect is also obviously different, it is recommended to carefully select high-quality materials and cooperate with contractors.

―

3. Working Mechanism

In general concepts, it is often believed that polyurethane crack sealant agent is water-swelling grout, which is not correct. After high-quality water-swelling grout when in contact with water, it produces a dense, airtight foam that is not decomposed by water and which blocks the flow of water.

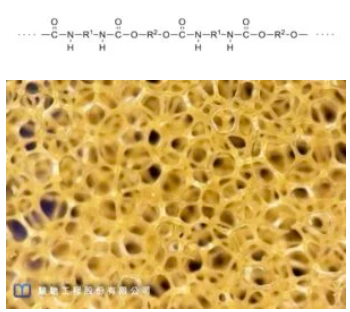

By observing the magnified image of IP-125 grout slices, it was found that the expanded bubbling was complete, the edges of the bubbles tightly bonded, with good sealing properties.

However, with either the water-swelling grout or the self-expanding grout, the water-blocking bubbles may cause local rupture after long-term use and temperature changes, and they cannot block water molecules with a diameter of only about 0.4 nm.

Therefore, after injecting the foaming expansion grout to block the flowing water, the non-swelling elastic or rigid second grouting must be done according to the structural characteristics to achieve long-term water stopping and reinforcement effects.

―

4. Supporting Methods

In order to achieve long-term water stop and reinforcement goals, in addition to selecting appropriate high-quality polyurethane grout materials, the method is also an important factor that determines the effectiveness of leakage water treatment. For ideal water seepage sealing, the grout must be injected as close as possible to the near end of the water side and fill the cracks.

Drilling is usually done staggered at a 45 degree angle. The intersection point of the borehole and the crack in the structure is about 1/3 of the thickness (wall thickness) from the water side.Under these conditions, the appropriate pressure is used to inject the non-expanding polyurethane grout, which can achieve the best long-term leak stop and reinforcement effect.

―

Polyurethane Crack Sealant Grout Material Classification And Injection Methods.

將下載檔案寄至:

・More Construction Result Sharing

Contact us:+886 2769-2355

Copyright ©Jines Construction Co.,Ltd