GROUT CURTAIN REINFORCEMENT TECHNOLOGY IN RESERVOIR WATER TUNNEL FRACTURED ROCK ZONE

Stratum Grout Curtain Reinforcement

1. Project Background

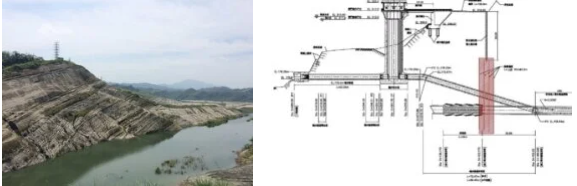

Grout Curtain : An additional water conveyance tunnel at a reservoir was connected to an existing water diversion tunnel.In the inclined pipe section, there was a region of about 9.5m of fractured rock, and joints had developed.

In order to ensure the long-term safety of the tunnel after completion, the design unit planned to carry out curtain grouting reinforcement in this section. Because the design was pre-planned, the construction method was to be adjusted according to the actual situation or the client’s instructions.

―

2. Solution

Because this was a pre-designed project, in accordance with the design requirements, the company adopted the following work plans:

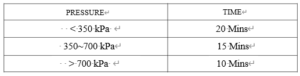

(1) Perform water pressure tests by drilling boreholes in stages to determine the proportions of cement grout material;

(2) Divide the range of curtain grouting range batches and boreholes, and use the 1-diameter method for grouting, so as to fill the rock joints, cracks and boreholes in the reinforcement range to form a continuous water-stop curtain;

(3) Use Leakage test (Lugeon Test/rock plate test) to be used to confirm the water permeability of the rock formation after grouting each borehole section;

(4) The test result is greater than 5 Lugeon borehole segments, supplement with grouting and testing, until the design requirements are met.

―

3. Works Design

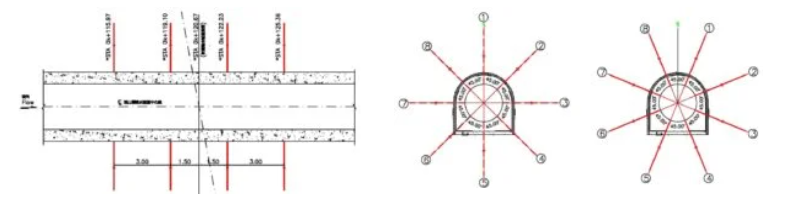

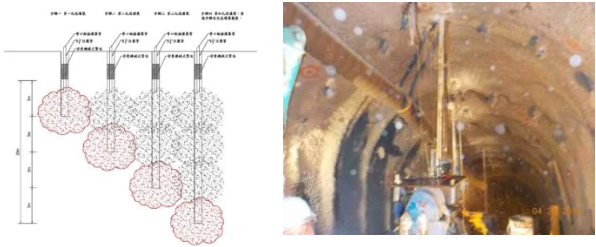

For the inclined pipe section of the water conveyance tunnel of length about 9.5m, 4 rings of curtain grouting are to be set up, and each ring has 8 grouting holes with a spacing of 3m.

The two adjacent ring holes are staggered, and each hole is 20m deep into the rock formation. The drilling and grouting to be carried out by the Downstage Grouting Method, and the grouting depth at 20m divided into 4 hole sections, and each hole section 5m in length.

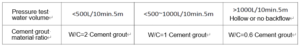

Cement grout to be used as the filling material, and the ratio of the grouting material to be determined according to the pressure test results compared with the following table.However, whenever the grouting pressure or volume is abnormal, it can be increased or decreased according to the actual conditions.

―

4. Works Process

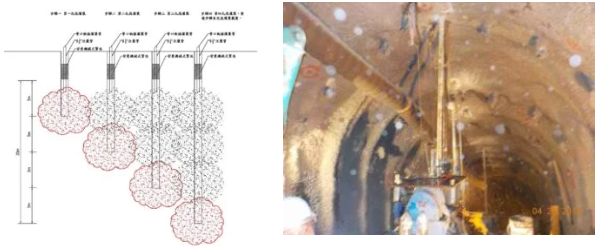

The construction site of this project was located in the tunnel of the inclined pipe section of the newly built water conveyance tunnel. The tunnel had only supports and first concrete lining.

In addition to adjusting the operation method appropriately according to the actual rock conditions during the construction process, a large number of work platforms and rigorous safety protection measures had to be set up, and a safety response plan had to be formulated to ensure the safety of the staff.

When arranging the work site, large-scale equipment such as generators, mixers, and pumping equipment were installed at the bottom of the pithead shaft, and only the drilling machine and grouting pipe extend to the filling position to facilitate flexible scheduling.

Because the degree of rock fracture is slightly different during pouring, the cement grout ratio was adjusted to a water-cement ratio between 0.4 and 4 according to actual conditions.

The grouting pressure of the borehole opening was not more than 2000kPa, and the injection pressure and the continuous grouting time with a use rate of less than 1 liter were used as the control point for the grouting completion of the borehole sections.

―

5. Results

The grouting process went smoothly, with only localized grout flowing out from adjacent grouting holes, primary fissures and external rock formations. With proper plugging, the grouting operation was successfully completed.

After the completion of the phased grouting work, the company called the entrusting experts to conduct an on-site leakage test. After confirming that the water permeability requirements of the grouted rock layer of the curtain were met, the site was delivered to the construction unit for subsequent work.

The grouting reinforcement work of the rock strata curtain was successfully completed.

―

・More Construction Result Sharing

Contact us:+886 2769-2355

Pool leakage Grouting Repair Case

將下載檔案寄至:

Copyright ©Jines Construction Co.,Ltd