SEISMIC REINFORCEMENT OF BUILDING ON SLOPING SITE AND REINFORCEMENT OF SURROUNDING FACILITIES

Filling and grouting of collapsed layer and reinforcement by micro-pile

1. Project Background

A public building was located on sloping seaside land. The geological conditions of the property included colluvial rocky mass with pebbles below, and interbedded sand and shale below that. This project was located in an earthquake-prone area.

While the building was in use, after several strong earthquakes, displacement cracks appeared parallel to the coastline on the side of the building looking toward the sea.

Shear cracks of different sizes also occurred in the property paving and building.Because the area was located in a frequent-earthquake area, after evaluation by our company, it was decided to carry out seismic reinforcement of building and surrounding facilities to ensure the safe long-term use of the various facilities.

―

2. Solution

This project was under the jurisdiction of the public sector.In the early stage of commissioned design, a four-stage implementation plan of “filling-improving-reinforcing-repairing” was adopted to reinforce the building and surrounding facilities.

For the geological improvement, cement-based grout to be used to fill the gaps in collapsed layers and consolidate among rocky mass.

For the reinforcement, close-packed micro-piles to be used to penetrate the improved rocky mass or rock formation to prevent relative displacement and lateral sliding caused by earthquakes.

After the above work is completed, and after monitoring has confirmed the seismic requirements are met, the existing structural cracks will be filled and repaired, and the original landscape will be restored.

―

3. Works Design

According to the research and judgment of the geological profile of this project, the location of the property belonged to the saddle type of the rock formation, and the thickness of the upper colluvial layer varied greatly.

After detailed design according to the design plan proposed by Party A, the construction plan is proposed as follows:

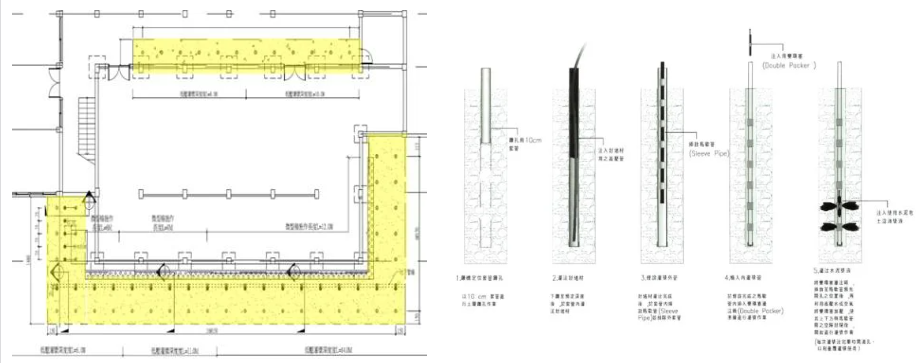

(1) Divide the geological improvement grouting range into three blocks A, B & C according to the characteristics of the building and strata.The scope includes the locations of the buildings and surrounding areas that may have differential deformation of the strata.The Double Packer Grouting method is adopted, and the hole spacing is 1.5m; the depth is 5~13m; the vertical grout outlet spacing is 0.5m for reasonable configuration.

(2) When the buried Marshall pipe is imbedded and poured with CB grout, if grout leakage occurs, a method of infusion and supplement shall be adopted to achieve the dual purpose of installing the pipe fittings and filling the gaps in the surrounding collapsed layer.

(3) After the CB grout curing is completed and split set, the method of skip hole and inverse grouting is adopted from the lower slope to the upper slope.The cement grout with a water-cement ratio of 0.8 to 2.0 is poured, and the grouting pressure is poured with a small initial pressure +50 to 200 kPa to prevent a large amount of grout from escaping and causing environmental pollution.

(4) After the pouring is completed according to the original design, perform supplementary grouting according to the specific points displayed by the automatic recorder to ensure that the stratum gaps are evenly filled with the improved grout.

(5) Select a representative location to conduct an on-site water permeability testing, and perform supplementary grouting at locations where the water permeability coefficient is less than 10-5cm/sec.

(6) When the geological improvement grout reaches the design strength, install densely packed micro-piles with a pile diameter of 15cm; a length of 6-12m and a pitch of 0.2m in a staggered arrangement, and anchor the structure to the foundation.

(7) When all the micro-piles are completed, and after monitoring to meet the design reinforcement requirements, special epoxy resin grout is used to fill and strengthen the structural cracks.

(8) After completion of the above work, the building beautification project and restoration of surrounding facilities will be carried out.

―

4. Works Process

The public facilities could not be suspended during the execution of this project.

In addition to detailed planning of the flows during the works process, material stacking, grout mixing, pumping and various power supply areas were set up outside the building to avoid excessive impact on the original facilities.

Underneath the property was a layer of hard collapsed rock with pebbles and gravel, so in order to achieve the best works efficiency, the drilling process adopted was self-propelled large and small pneumatic percussion drilling rigs to perform outdoor and indoor grouting holes and micro piles respectively.

Because the company has extensive experience in similar projects, the works process went smoothly, but the underground pipelines in some areas were complicated.The works process required temporary verification of pipelines and restoration, which consumed more time and manpower.

―

5. Results

Because the scope of this geological improvement belonged to the porous colluvial layer, it was not easy to grasp the quantity of grout materials used, which relatively increased the implementation cost.

Fortunately, under the rigorous working attitude of the company’s professionals, the overall geological improvement and micro-piling work went smoothly.

After conducting multiple tests such as on-site permeation tests and grout compression tests with the client, all the implementation results met the design requirements as scheduled and with good quality.

The seismic reinforcement of buildings om sloping ground and the reinforcement of surrounding facilities had been successfully completed.

―

Seismic Reinforcement of Building on Sloping Site

將下載檔案寄至:

・More Construction Result Sharing

Contact us:+886 2769-2355

Copyright ©Jines Construction Co.,Ltd