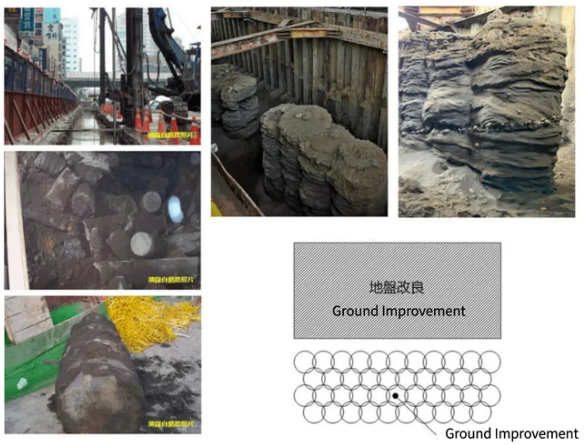

1. Ground Improvement is not Limited to High-Pressure Jet Grouting

- Ground improvement: high-pressure jet grouting (replacement method):

- Effective regional formation improvement

- Careful evaluation of water sealing effectiveness

- Water-stop curtain – comprehensive reduction of soil permeability depending on ground conditions – unsuitable

―

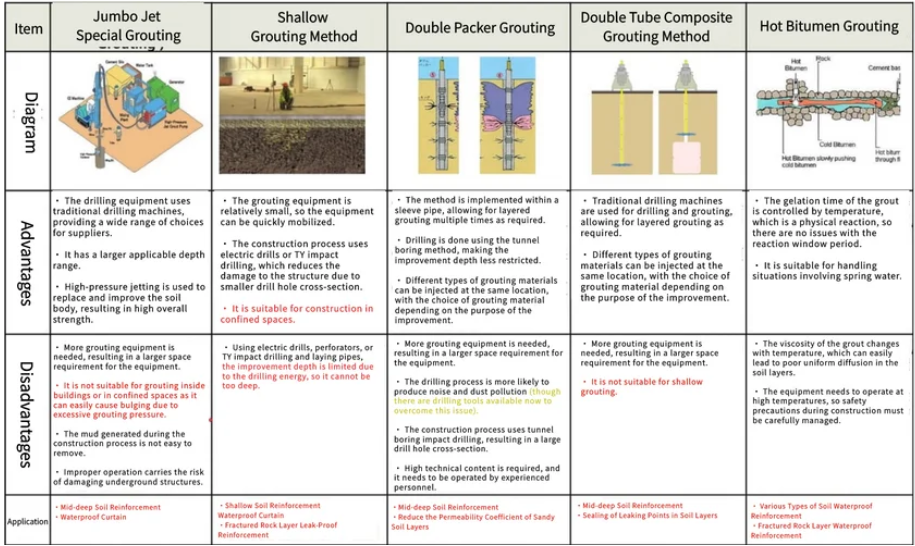

2. Grouting Methods for Ground Improvement

―

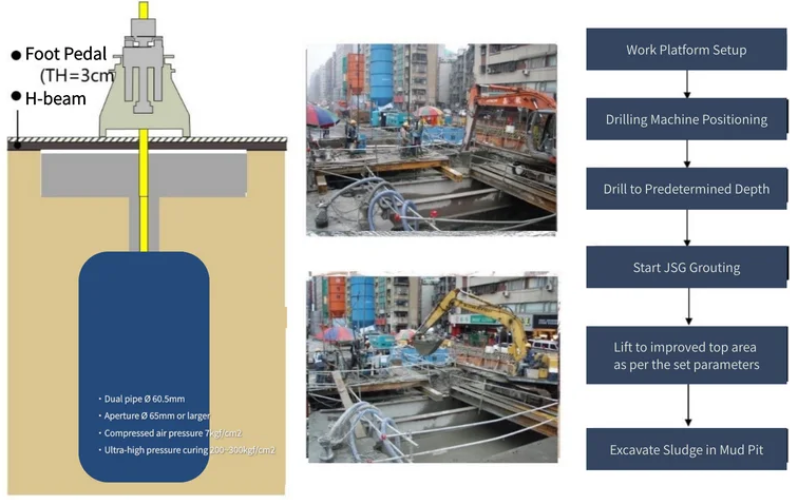

2-1.Ground Improvement : High-Pressure Jet Grouting Method

The High-Pressure Jet Grouting Method is a displacement technique that utilizes high-pressure water, compressed air, and high-pressure grout. It involves injecting them into the ground through small-diameter nozzles to cut through and affect the surrounding soil.

Taking advantage of the air density < water < grout characteristics, this method displaces the localized (or majority) of soil and pore water, allowing the grout to replace the evacuated voids and mix with the remaining soil. This process forms underground columnar consolidation bodies through displacement. — (Excerpt from High-Pressure Injection Grouting Method Introductiong)

―

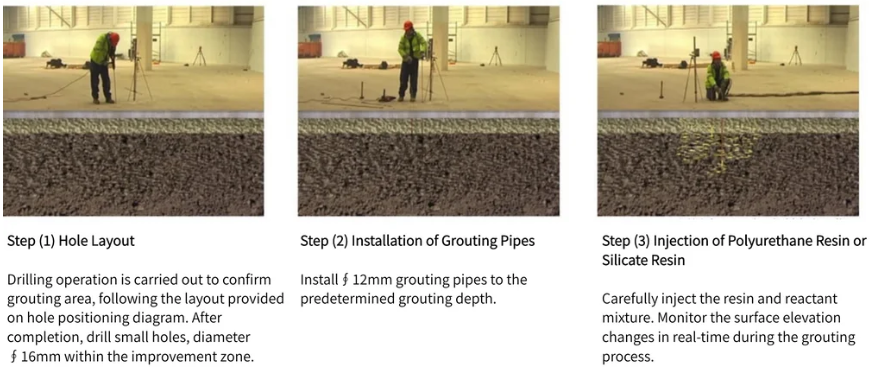

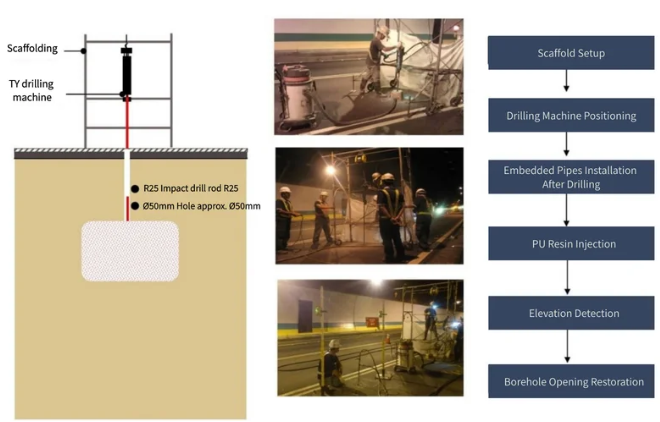

2-2. Ground Improvement : Shallow Ground Grouting Method (Depth ≤ 2m)

Single-Seal Grouting(Shallow Grouting Method) is a grouting technique used within 5 meters below the ground surface.It involves the use of small-diameter drilling and small-caliber grouting pipes to inject suitable grout materials into the ground.

The aim is to achieve purposes such as raising pavements, structures, and buildings, sealing leaks, stopping water inrush, filling voids, improving ground conditions, and reducing local hydraulic conductivity of the soil.

During the grouting process, the annular space between the borehole and the grouting pipe needs to be sealed.It is commonly performed using a 1-diameter or 1.5-diameter slurry pumping method, with grouting pressures ranging from P0 +1 to 35 kg/cm2.

During the grouting operation, it is necessary to have a monitoring system in place to observe and prevent any potential secondary damage to structures. — (Excerpt from Single-Seal Grouting Method Introduction)

―

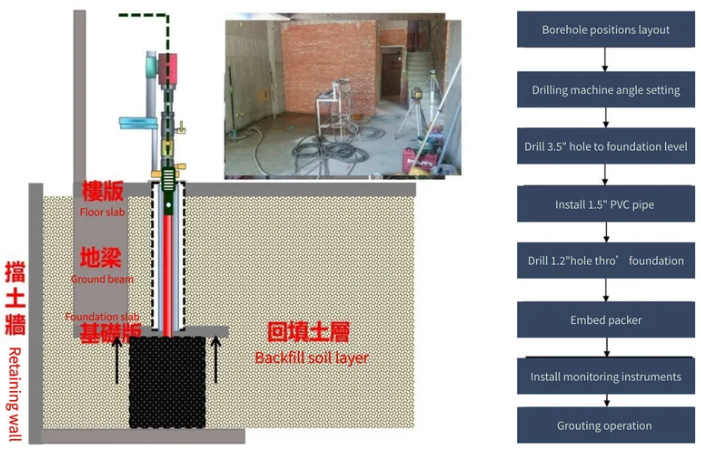

2-3. Ground Improvement : Shallow Ground Grouting Method (Depth ≤ 5m)

―

2-4. Ground Improvement : Single Tube Packer Grouting, Depth ≤ 5m

―

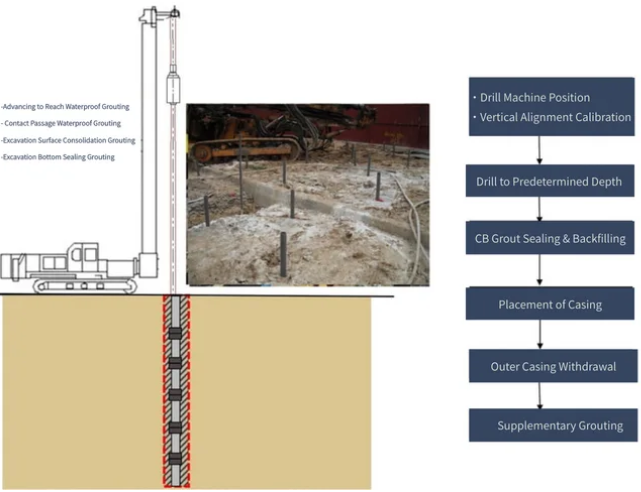

2-5 Ground Improvement : Double-Packer Grouting Method

Double-Packer Grouting also known as Marshall Pipe Grouting or Double-Ring Grouting, is a low-pressure injection technique that allows for repeated injection of different grout materials.

It involves the installation of outer grouting pipes in the ground at regular intervals, typically equipped with check rubber sleeves (@33.3cm or @50cm). These pipes are accompanied by movable upper and lower packers that can be inflated or filled with water to seal off specific sections of the outer grouting pipes.

This setup allows for multiple injections of different grout materials at various locations. Double Packer Grouting is primarily used in various applications such as reducing the permeability of the ground, sealing water leakage, ground improvement, liquefaction prevention, and soil remediation.

The grout material typically permeates the soil particles’ voids in sandy layers and exhibits a vein-like infiltration distribution in clay or silty soil layers. This method is suitable for a wide range of applications as it involves low-pressure permeation, causing minimal disturbance to the ground. — (Excerpt from Double-Packer Grouting Method)

―

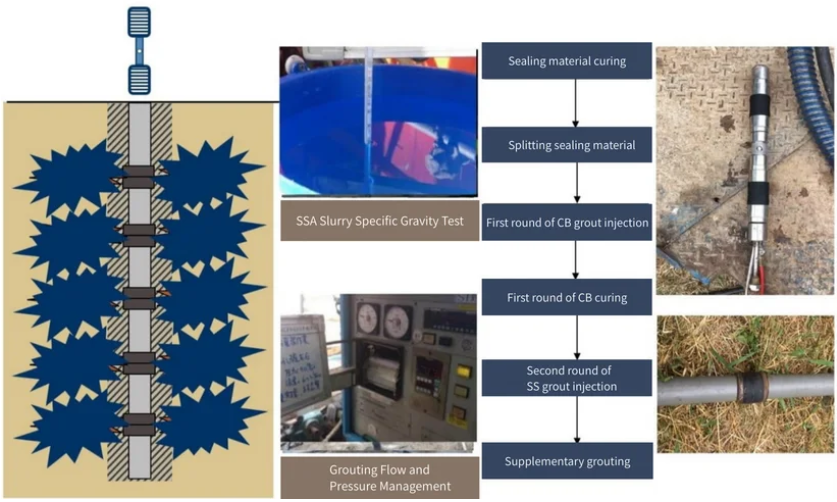

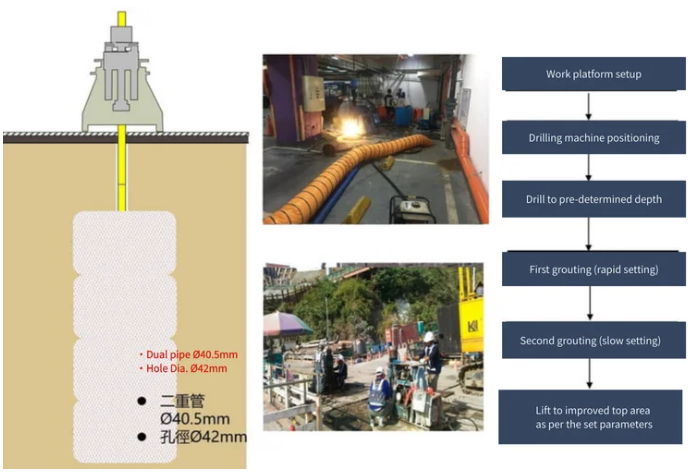

2-6 Ground Improvement : Dual-Pipe Grouting Method

The Dual Pipe Grouting Method is a versatile low-pressure grouting technology suitable for various formations and grout materials, with adjustable grout curing time.

In this method, the strata are treated through 50cm sequential or reverse grouting intervals, allowing for effective treatment of compacted, split, vein intrusion, or plugging.The unique characteristic of the double-layer pipe lies in the separation and mixing of inner and outer pipe grout materials at the pipe’s opening.

This facilitates the adoption of a two-diameter grouting mode, combined with instant-setting or slow-setting slurry materials, enabling precise control of solidification time and grout advancement distance in the formation. — (Excerpt from Dual Pipe Grouting Method)

―

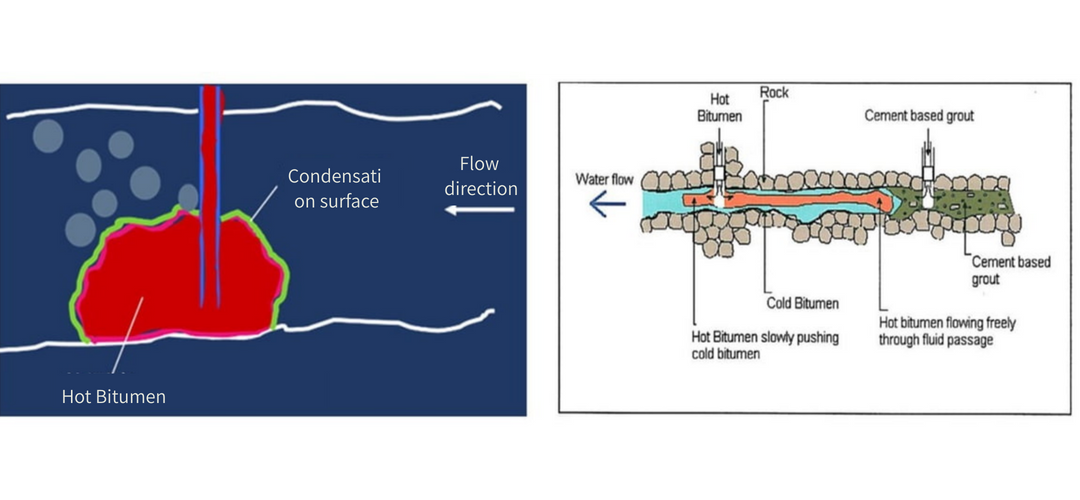

2-7. Ground Improvement : Hot Bitumen Grouting Method Principle of Bitumen Grouting

Hot Bitumen Grouting Method is a specialized technique that utilizes a specific type of bitumen that exhibits a liquid state at high temperatures and rapidly increases in viscosity when in contact with groundwater or as it cools.

This method is employed in areas with flowing water, high volume water inrush, or areas of extensive leakage to effectively seal off and fill voids.The process involves injecting the hot bitumen into rock formations, structural cracks, or weak geological layers by utilizing the steam pressure generated during the grouting process.

This allows the liquid bitumen to flow into the desired areas and form a waterproof layer, effectively blocking water infiltration. Hot bitumen grouting is characterized by its “later in, goes first” nature, meaning that the hot bitumen is injected after it is melted and can flow through previously solidified bitumen, effectively filling various large and small cracks.

This method ensures comprehensive sealing of water inrush and achieves the desired waterproofing effect. — (Excerpt from Hot Bitumen Grouting Method)

–

Traditional grouting methods often face difficulties in effectively consolidating and sealing due to high water flow rates or other challenging factors, resulting in the loss or dilution of grout material.

The setting process of bitumen grout is primarily controlled by temperature.

When flowing water comes into contact with hot bitumen grout, the temperature of the grout decreases rapidly, causing its viscosity to increase quickly (bitumen viscosity is highly sensitive to temperature changes), leading to rapid solidification at the water contact zone.

The hot bitumen grouting technique is highly effective in sealing and addressing water inrush issues in cofferdams, seawalls, excavations, and tunnels. It provides excellent results in these applications.

―

3-1. Objectives of Grouting

◆ Increasing Bearing Capacity. ◆ Increasing Shear Strength. ◆ Enhancing Consolidation.

◆ Preventing Soil Liquefaction. ◆ Sealing Water Infiltration. ◆ Preventing or Managing Hydraulic Pressure (Buoyancy) Damage.

◆ Treating mud spray. Reducing Porosity, Increasing Unit Weight, Lowering Water Content, Enhancing Cohesion, Increasing Lateral Stress on the Ground, Decreasing Permeability, Filling Voids

―

3-2. Selection of Grouting Methods for Ground Improvement

◆ Assessing the project conditions to identify suitable grouting techniques.

◆ Choosing effective grouting methods from the available options that are suitable for the project.

◆ Selecting the most cost-effective technology and materials from the effective grouting methods.

◆ Evaluating whether the desired grouting objectives can be achieved within the allotted operation time.

◆ Seeking advice from professional entities to gather their expert opinions.

―

・More Construction Result Sharing

Copyright ©Jines Construction Co.,Ltd