GROUTING REPAIR FOR POOL LEAKAGE

Swimming pool damage investigation and repair technology

1. Project Background

After a university swimming pool was in use for a period of time, localized cracking, water leakage, and mud inflow around the water inlet occurred.

In order to restore the swimming pool to normal use as soon as possible, the school maintenance unit submitted and prepared a budget.The client put the repair job up for tender, and selected the best contractors for the project.

―

2. Solution

The project contract aimed to deal with water leakage and mud inflow problems within a time limit, so on undertaking the work, the company immediately followed the contract requirements using site survey results to plan the restoration, as follows:

(1) Investigation of the distribution and width of cracks in the swimming pool

(2) Pool structure horizontal measurements

(3) Investigation of water inlet pipeline and filtration system

(4) Repair the cracks in the pool structure

(5) Replace the water inlet pipeline

(6) Use of ground penetrating radar to probe the repair status and substrate condition, and propose a foundation reinforcement plan.

―

3. Works Design

According to the on-site investigation, the existing cracks were mostly short-directional regular cracks in parallel.No shear cracks were found.

During the horizontal measurement of the pool structure, it was found that there was a differential settlement of the foundation, and the large variable angle was mostly concentrated on both sides of the parallel cracks.

These were adjacent to the expansion joint of the swimming pool foundation second construction.Based on the above investigation, the damage to the swimming pool would have been caused by the foundation sinking or floating, causing the original weak surface of the foundation to crack and the water inlet pipe joints to partially fail and leak water.

―

4. Works Process

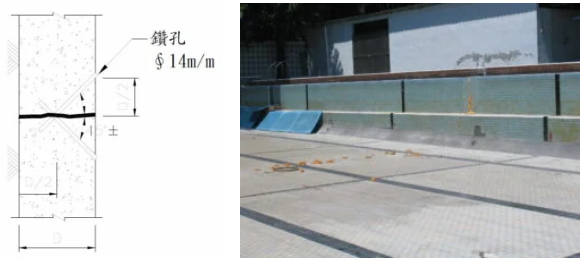

According to on-site measurement results, the width of the cracks in the pool was about 0.1mm~0.7mm, which was suitable for repair using resin grout.

However, because the swimming pool cracks were filled with water at that time and there were load differences and structural deformations in the future works, the following methods and materials were adopted as reinforcement techniques:

(1) Cleaned out the debris and dirt in the cracks

(2) Stagger filled 45-degree oblique holes along the cracks, and located the resin injection position at the rear edge of the middle section of the foundation

(3) Pressure grouted to stop leakage, using water-swelling polyimide resin until the resin flows out from the next pouring hole in the sequence. The process flow had to be the sequence of outflow of water, swelling resin, and non-swelling pure resin

(4) After standing for more than 5 minutes and within 15 minutes, continued to inject the high-adhesive non-swelling elastic resin for structural repair from the original injecting hole until the resin overflowed on the surface of the next grouting hole and crack.

The inlet pipe was not suitable for large-scale excavation and repair because it was deeply buried in the ground and the location of the leak was not clear.After evaluation, it was decided to fill and seal the old pipeline and its surrounding backfill with a self-swelling resin for leak stop, and to configure a new pipeline to permanently repair the water inlet pipe leakage and the surrounding mud inflow.

After all the work was completed, used quick-setting cement, resin mortar and lightweight concrete for filling, repairing and surface treatment of the reinforcement and excavation sections.

―

5. Results

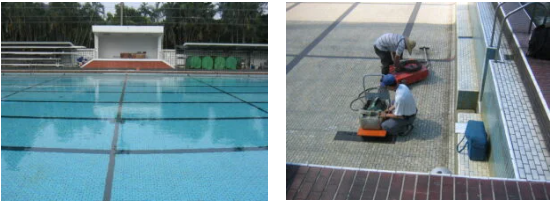

Because this reinforcement project was carried out with oblique-angle staggered two-stage grouting, the overflowing unreacted swelling resin filled into tiny gaps that cannot be distinguished by the naked eye, and a water-block layer was formed on the water-facing surface to prevent leakage from happening again.

After the completion of the reinforcement operations, there was no leakage after ground penetration radar detection and repeated water injection tests.

When the ground penetration radar detected that there was partial soil hollowing and softening in the substrate layer, the company, in accordance with the spirit of the contract, detailed a substrate reinforcement plan and handed it to the client to deal with separately.

The leak and filling repair of the pool structure was smoothly completed within contract time.

―

Pool leakage Grouting Repair Case

將下載檔案寄至:

・More Construction Result Sharing

Contact us:+886 2769-2355

Copyright ©Jines Construction Co.,Ltd