LEAKAGE SEALING AT MANHOLE MAINENANCE ROOM AND PIPELINE CONNECTIONS

Small-diameter pipeline leak-stopping grouting tech in confined spaces

1. Project Background

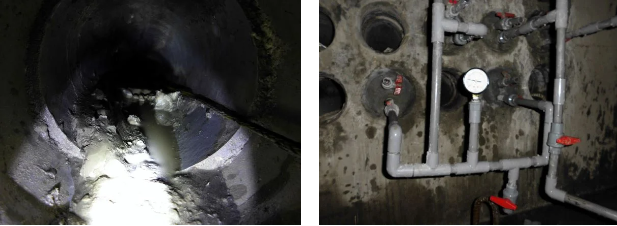

An industrial area uses embedded PVC pipelines to connect various cables. There is a manhole maintenance room set up between the pipelines to facilitate construction and any maintenance.

After a period of use, it was found that some embedded pipelines leaked water, which caused the manhole shaft to be severely flooded and could not be used normally.

In order to avoid further damage, the maintenance unit commissioned a professional contractor to draw up a treatment plan, and deliver it for implementation after passing review.

―

2. Solution

Because the embedded PVC pipeline was long, the location of the leak uncertain, and the available work space limited, when planning the leakage plugging, the implementation steps were formulated as follows:

(1) Pumping out water and pipeline cleaning;

(2) Leakage detection;

(3) Sealing with Plug Grouting Technique;

(4) Use of long-term low-strength sealing materials for water stopping, so as to facilitate the pipeline operation after construction;

(5) The blockage effect is ensured by segmented multiple low-pressure grout injection.

―

3. Works Design

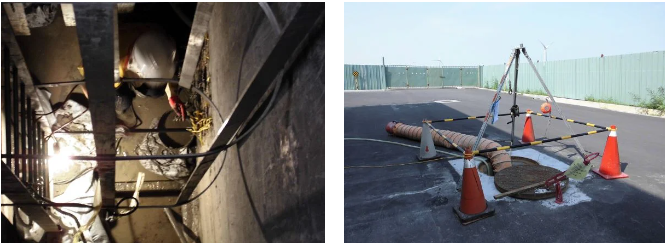

Because the working space available in the maintenance room was small, large-scale construction machines, grouting pumps and other equipment could not enter the shaft, and a long-distance material supply method was planned for the works design:

(1) Slow-setting long-term saline-alkali-resistant SSA chemical grout to be used for grouting, and the viscosity controlled at about 2cP;

(2) Grouting using the casing grouting method;

(3) Use an electronic endoscope to detect the location of the leak; use single casing grouting and a nozzle to seal the leaking point close to the maintenance room PVC nozzle; use double packer grouting to seal the leaking point at a distance from the nozzle;

(4) Each section to be grouted three times; grouting pressure to be not greater than 350kPa;

(5) After the grouting is completed, conduct pressure tests to determine the plugging effect.

―

4. Works Process

After the manhole shaft was pumped out, an endoscope was used to examine the pipeline. It was found that there were localized accumulations of fine particles of soil and mineral crystallization in the pipeline.

After reciprocating cleaning with a perforator buried rope and a steel brush, the water leakage point is calibrated.

After using a perforator to bury a rope-bound steel brush for reciprocating cleaning, the leaking points were marked. Pressure-expanding plugs were inserted before and after each leak point.

To accommodate the low-pressure grouting operation in a confined space, a small-diameter PVC pipe was used in conjunction with a proximal pressure gauge set in advance.

This eliminated the difficulty of traditional grouting methods involving personnel, tools, and grouting pipes in small spaces.

In the staged grouting process, a retarded chemical grout (SSA) was first used to penetrate the surrounding strata, reduce the permeability coefficient of the surrounding stratum, and fill in holes and water pathways.

After the first grouting material began to gel, the second and third groutings were carried out to effectively seal the interface between the pipeline and the stratum, as well as the joints and gaps in the pipeline.

―

5. Results

After completion of the grouting and curing process, a pressure test was conducted using a water pressure not less than that of the groundwater head around the maintenance room, to confirm the good sealing condition.

After confirming that there were no leaks in the pipeline during the observation period specified in the contract, the grouting pipes were removed, the openings sealed, and any remaining low-strength solidified grouting material in the pipeline was cleaned out.

The work of sealing the leakage at the joint of the manhole maintenance room and the pipeline was successfully completed and reported to the commissioning unit for acceptance.”

―

Leakage Sealing at Manhole Maintenance Room and Pipeline Connections

將下載檔案寄至:

・More Construction Result Sharing

Contact us:+886 2769-2355

Copyright ©Jines Construction Co.,Ltd