INTRODUCTION TO RIGID FOUNDATION PRECISION JACKING APPLICATION

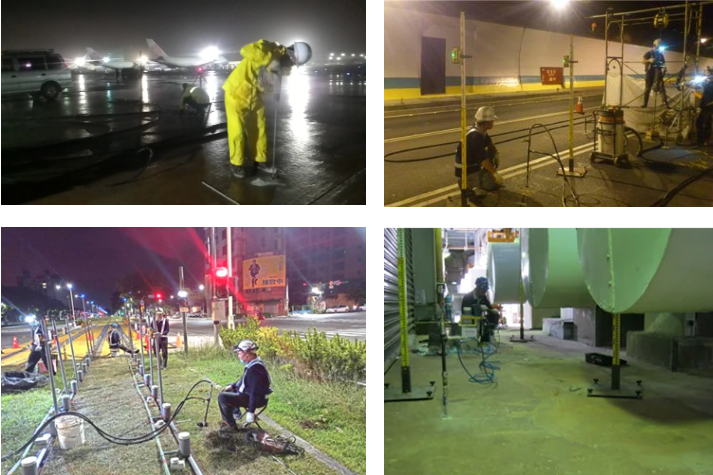

Micro-drilling grouting and monitoring technology

1. Project Background

For rigid foundations such as rigid roadbeds of expressways, airport taxiways, MRT system track slabs, precision workshop foundations, etc., once the stratum below the foundation is disturbed, subsidence of different scales may occur.

After subsidence occurs, the behavior of the rigid base slabs will be different from that of the stratum due to the stiffness disparity. At this time, there will be voids or weak zones in the foundation, accompanied by phenomena such as mud spray, cracking and water seepage, or track deformation.

―

2. Solution

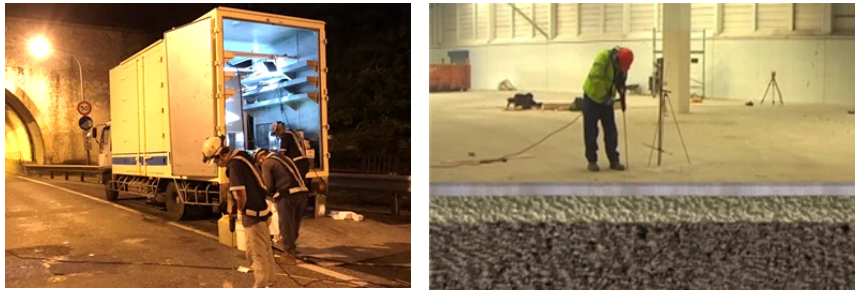

In the past, to solve stratum subsidence under rigid foundations, cement mortar, cement bentonite grout and other materials were mostly used for filling and jacking. However, due to slow setting time, cement-based grout cannot solidify within the short 3-4 hours while the traffic system stops operating at night.

As a result, with traffic systems operating during the day, the cement grout that had not yet solidified could be crushed and disintegrate, causing subsidence to occur again.

The new low-viscosity non-expanding rigid resin grout is suitable for a new generation of rigid foundation reinforcement and lifting material due to its advantages of good flow and filling, fast and controllable curing time, small drilling hole diameter, and high flexibility of construction equipment use.

―

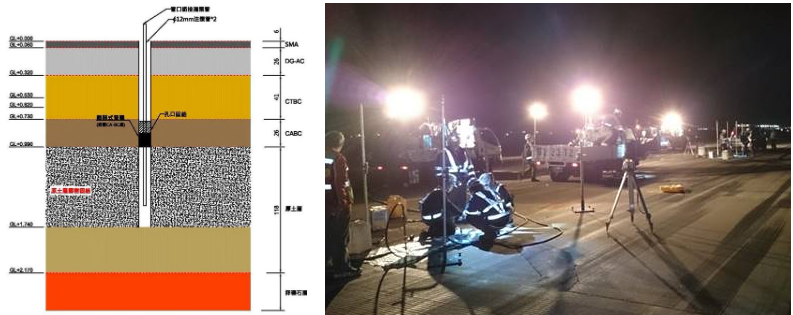

3. Works Design

The curing time of the new resin grout is about 20 to 180 seconds. With the single-ring plug grouting method with an opening diameter of only 15~20mm, shallow subgrade filling, splitting, and compaction reinforcement within 3m can be carried out; base slab jacking and cavity filling; with small sleeves for deep subgrade compaction grouting and other site improvement work.

It can effectively strengthen the subgrade, provide sufficient reaction force to lift the rigid foundation, restore the design elevation of the foundation, etc., and has improvement effects on the shallow and deep subgrade, so the rigid foundation no longer has differential subsidence.

―

4. Condtions Control

There are three elements that must be mastered in the rigid foundation jacking process:

(1) Stratum reinforcement, foundation jacking, and hole filling performed in sequence;

(2) The strength of the grout and the curing time are to be fully controlled;

(3) Real-time and accurate monitoring of each process.

Only when the above three tasks are done well, can the precise lifting and reinforcement grouting be achieved. Among the above three elements, accurate monitoring and control are the most important.

Use of appropriate monitoring equipment, such as: total station and level gauges with an accuracy of 0.1mm, automatic scanning laser level with an accuracy of 0.5mm, and a continuous subsidence gauge with an accuracy of 0.1mm, etc.

Real-time monitoring and cross-comparison are to be carried out in the range of 5m jacking grouting radius of influence. Only then can the lifting, reinforcement effect and safety be ensured.

―

5. Application Points

To do a good job of lifting foundation slabs, each jacking should be carried out from the maximum subsidence point of the section. The distribution of jacking holes varies according to engineering conditions. Generally, it should not exceed 1.0m~1.5m, and the grouting holes can be reused.

Jacking must be applied in stages, and the amount of jacking should not exceed 5~10mm each time, so as to prevent the superposition effect of grout channeling and the stiffness of the base slabs, resulting in excessive jacking.

―

Leakage Reduction Grouting During TBM Tunnel construction

將下載檔案寄至:

・More Construction Result Sharing

Contact us:+886 2769-2355

Copyright ©Jines Construction Co.,Ltd